How to learn and practice trad building:

First is the study of architecture itself. At the material and labor level of operations Architecture is simply programming or planning what will be, before it occurs.

This is why we call them the “specifier” class now. In trad building you learn by specifying your own labor first. then you practice by testing that labor and performance before a jury of elders.

In this way trad building is much like solo climbing. A mountaineer would be disregarded if they stayed at base camp and simply specified the efforts of sherpas on the mountain. We would not allow them to take credit for the ascent. Yet the entire field of professional architecture is built on this premise..

Buildings require planning and labor to occur. They do not require a specifier class however. The specifier class requires itself.

So what is required? Well, start by setting off a task model. Here is an example of a task model:

Build a 1000 year lifespan “Roman” floor 10×10 encased within 2 wythe bonded wall. Record total calories in and man hours. Derive a ratio to describe the building as total calories over expected lifespan. Translate to modern price per square ft metrics.

Ingredients: quicklime; brick, earth, gravel

Tools: typical pre industrial methods and tools with power assist practically applied where process is not effected.

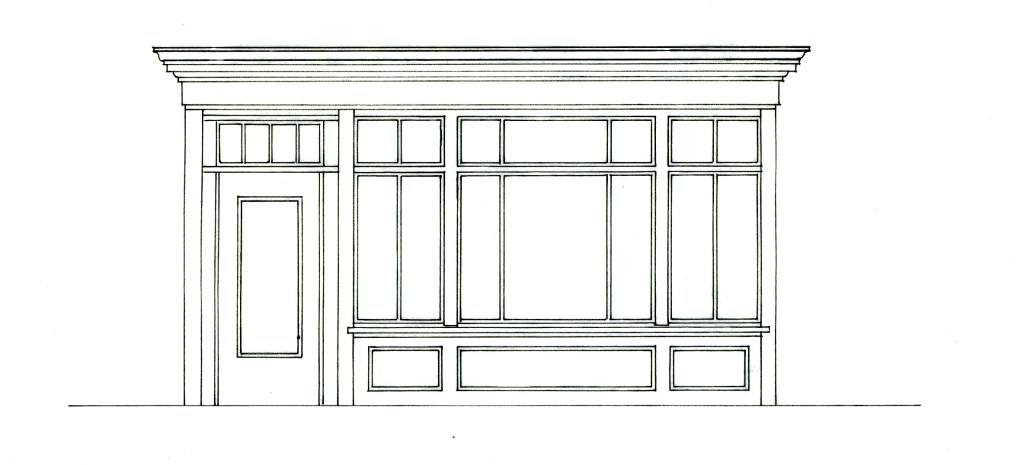

The “Classical Design” post

I really don’t care for it. but if we must, let’s imagine a single bay storefront on a Chicago 2 flat live/work unit. I did just that a few times when I lived there in 2011. “Practical” minimal classical design, specifying lots of millwork to reach a style. New urbanist would come to love this idiot catnip and specify it everywhere thinking commerce is the answer to social problems, and housing. Equity is the issue. If people own the structure they live and work in, it makes a lot more sense than if its knocked up out of plywood by a developer and made to look like this for “fashion”

Corinthian order was invented to celebrate the sex bodies of Corinth

What are the “origins” of classicism? In the apostle Paul’s letters: he writes of how slutty and filthy all the little fuckers are over in Corinth. Famous for its public gay sex parties and working girls! (call me, sounds like a great time)

Let me perform some intellectual honesty and give credit to the OG “Cuban American” fancylad I stole this thought from. Victor Deupi gave a lecture at a “trad” architecture conference in 2007, in New Orleans. He merely whispered it, without performing any materialism and moved on quickly to being lost in the “beauty” and some other dumb shit about how the order is like a sexy woman that you can “just” capture…. Why are you capturing women?. Victor Identified the mode of production in Corinth was mostly sex work and port activities. He marched right up to the edge of perception and turned away, to sell art, he performed a fantasm to explain the order in his talk, rather than science of materials and conditions. Over at the adults historian table: we perform historical materialism bud.

It’s just duty and service to actually perform the stone carving. It takes athletic bodies and hard focus. That real uncut gym footage. Homo shit. Ripped chads bending, and flexing, and glistening. Rocky, be still!

There’s no hidden mystery. Tectonics of stone give the structural form. Then you subdivide it and make it all “greibled” with curves. Here Victor, let me complete your thesis for you, and say it with my chest: In Corinth since it was a party town, they had vulvas and twinkholes on their mind as much as plants. It’s a shrine to fucking and sucking. The good stuff.

Congratulations we just demystified your weird profession. Now, why do you need a retainer? Why are you valid?

Meanwhile in Corinth: grand buffet killed it last night every body got lit and forgot depressions.

Tradbuilding

Dudes rock. Also 1/3 of building labor thru history is women and boys

Style is a myth

Wood

Classicism doesn’t actually exist. I looked for it when I was building a molding plane to cut a raking cyma made out of wood from a tree that never should have been harvested.

Stone

I looked for classicism when I was dutifully carving task models of the orders out of Bedford limestone, I found myself laughed out of academia.

Metal/Form

I looked for classicism at Monticello and found a master tinsmith enslaved, rude notes from his owner about his “performance”.

I can’t actually find “it”. Oh I looked in Delorme too, and Vitruvius. I went to conferences and attended molding theory lectures under halogen lights. I found salesmen in polo shirts with beach tans. And shashmaster Duffy Hoffman screaming into the void, the polished “Historical” crowd calling him a mean drunk….

What I can find in the classical building literature is authors telling me what to do with stone, wood, or how to perform stereotomy, they talk about subdividing and proportions as manual steps performed. When I follow their rules, I find the academy of classicism hostile to the labor.

There are no elusive hidden properties, or lost arts. Just tedious steps on how to walk a compass out, subdivide space and stretch circles. Just tedious steps on how to construct elaborate patterns.

Carpenters and sparrows, alike. cry in the corners of the roof.

It’s all physical process you can follow step by step to please your masters and specifiers. I can’t find any mysteries in the literature dang it, just a ton of hard work.

I just can’t find it. Where did it come from?

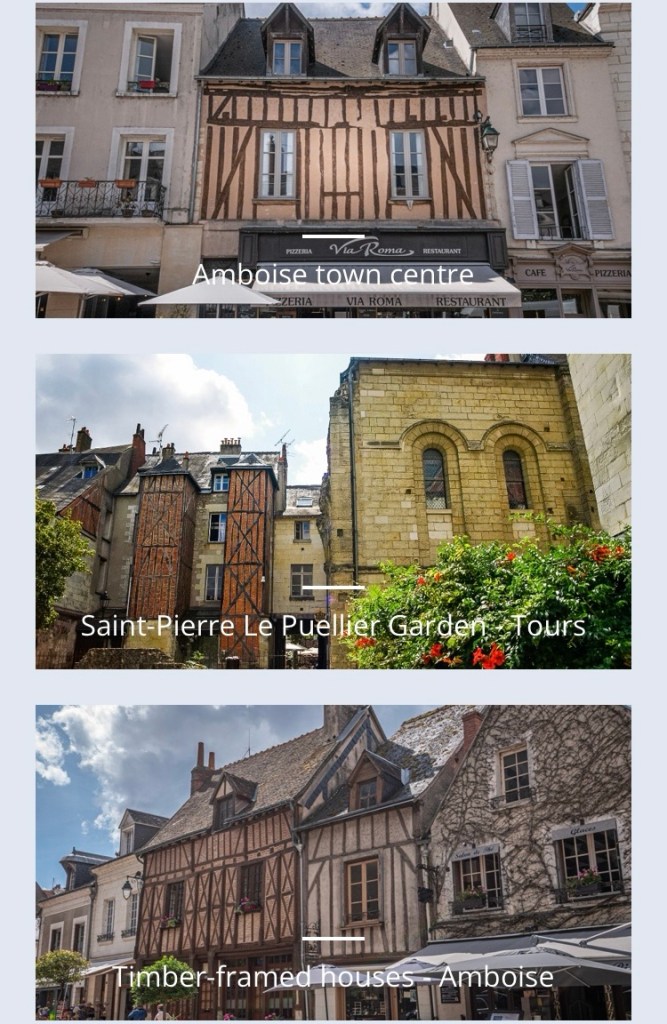

De l’Orme, a search for circular economy in 16th century France

Whenever in history there was a shortage of building materials, creativity was needed and often a circular approach was the answer. In the 16th century, the French Philibert de l’Orme invented a new building method, the so-called “à petit bois”, in which large roof spans were made of small pieces of wood. I was struck by the beauty and the genius who designed it, visiting the barn of the chateau Maurier in France. This method could be one of the first intended circular construction solutions ?

France in the 16th century was a place and a time where big wooden beams were expensive and barely available (*). The classical way of building, with big wooden trusses, was not an option anymore. In his book «Nouvelles Inventions Pour Bien Bastir Et a Petits Fraiz» (Ed.1561), Philibert de l’Orme described an alternative way of building, which is as simple as effective.

With still affordable and available short wooden battens, about 1.30m long, he managed to make huge roof spans, by a very clever “meccano” method of “nailing” them together with dowels. This is a solution which can be seen as the precursor of modern glulam beams. Scarcity of materials as a driver for a circular economy.

Only two types of these battens were needed. Prefabrication of thousand exactly similar wooden pieces could take place in a very cost-efficient way. Modularity as a characteristic of a circular economy.

Illustration : Ph. De l’ Orme, dans «Nouvelles Inventions Pour Bien Bastir Et a Petits Fraiz» (Ed.1561) ; only two types of prefabricated battens are used.

Whenever a piece of wood was infected or broken, it could easily be replaced by a similar one, without the need of breaking down a whole structure. Interchangeability and reversible joints as a characteristic of a circular economy.

Above all, by designing the roof in a form of an arch, or in the form of two arches (like an inverted boat-hull), the material is optimally used. There is no material underperforming its maximal strength. A clever design and a dematerialisation are the first steps in, and the key-factors of a circular economy.

Even though aesthetics were surely not considered to be important in the design of barn roofs in the 16th century, they do play a role in giving a building or building materials multiple lives. And this is what circularity in the design and construction is about.

The barn of Chateau de Maurier, Fontaine-Saint-Martin (F) , architect unknown, inspired by Philibert de l’ Orme, photo : BLIEBERG Architects of a circular economy

Philibert de l’Orme, once a famous architect on the court of Henri II (who designed e.g. the ballroom of the castle of Fontainebleau), fell in disgrace after the death of the monarch. Two years later, he wrote an appendix to his written chef-d’œuvre in which he gave a solution for people who could not afford expensive methods of building.

Kris Blykers, BLIEBERG architects of a circular economy http://www.blieberg.eu

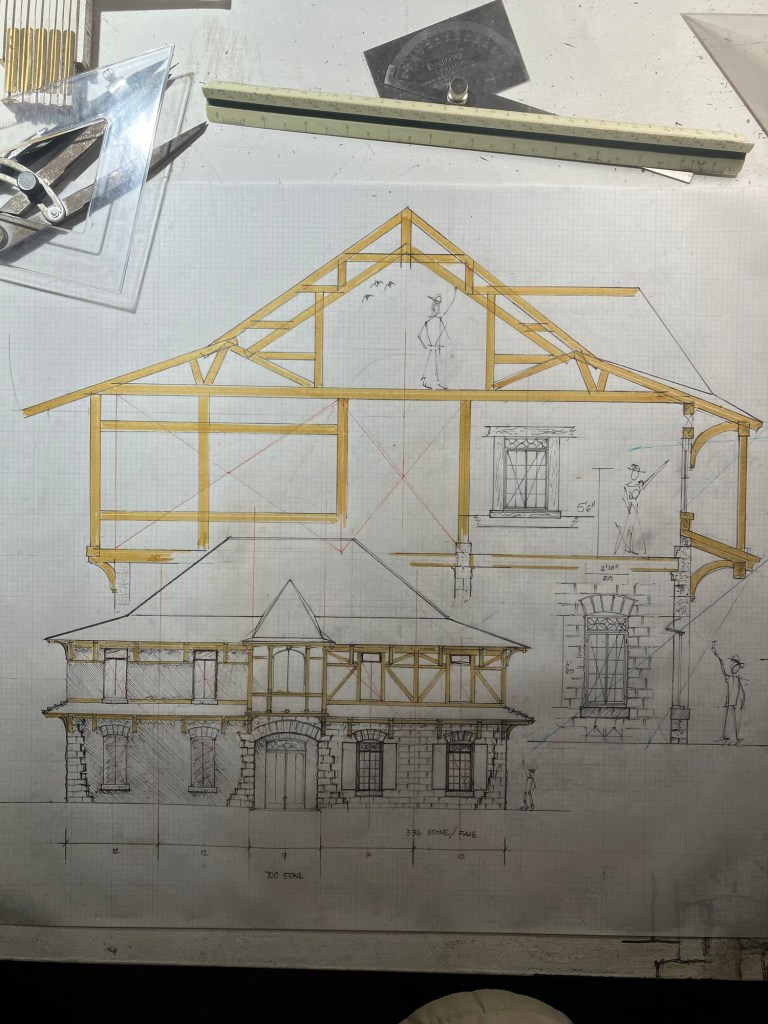

Fixing the Brent Hull French House

I came across a new type of guy. Crown molding factory owner, Brent Hull, who is doing some real “gee wiz” style commentary on traditional building. I’ve performed a critique on his design. Of course we’re using real stone, and timber frame right Brent? Why reinvent the wheel?

Brent’s design changes don’t offer much structurally. It’s still a suburb tract house sneering at the real thing. Brents design features a lot of consumption of millwork and products to produce “fashion”.

Rather than implying “French” with factory products stuck to a spec house…. Why not build French, and fitting the region.

These building methods have worked for thousands of years. This style is also specific to the region. French, German, Dutch, and Spanish colonial era builders used this means and method exactly to make their structures in Texas.

Mass walls, a “big tent” roof, and excellent cross ventilation, keeps the interior cool in the blazing heat.

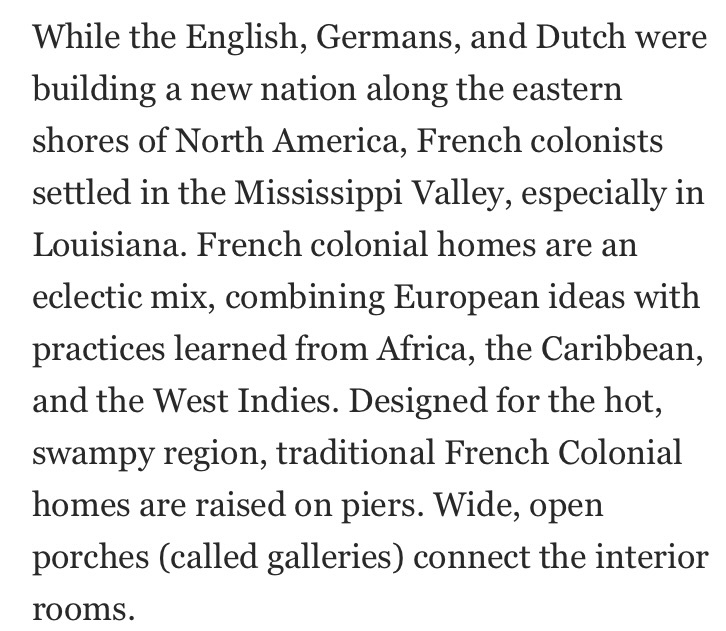

The changes here are: real materials for structure and sash. I didn’t change the “size” of the house just imagined it as a real one. Stone first floor, timber upper. Corbeled dormer over entry. The millwork entry is gone. Instead the structure of the stone wall and arch provides the punctuation.

What’s the point of the structure? 14 courses of 8”x12” stone. Thats the whole thing. Inside you plaster. On the exterior there is no need for appliqué or trim, the structure itself is beautiful. Instead of punching up the millwork and tack ons, everything we see here is doing a function. The arch stone set-back for the entryway gives it plenty of punctuation, and will convey importance and mass by simply being an impressive stone arch, in contrast to the spindly glazing of the French casement doors. It does what it says on the face.

Instead of the “extra” doors that go nowhere, we fit steel casements with leaded glass transom. The only “decorations” that are not serving function.

The second floor is post and beam structure with full joinery. Brick in-filled and stucco give the wall mass and provide backing for full plaster inside. We’ve avoided manufactured products for every thing but the glass and steel hardware for the steel sashes.

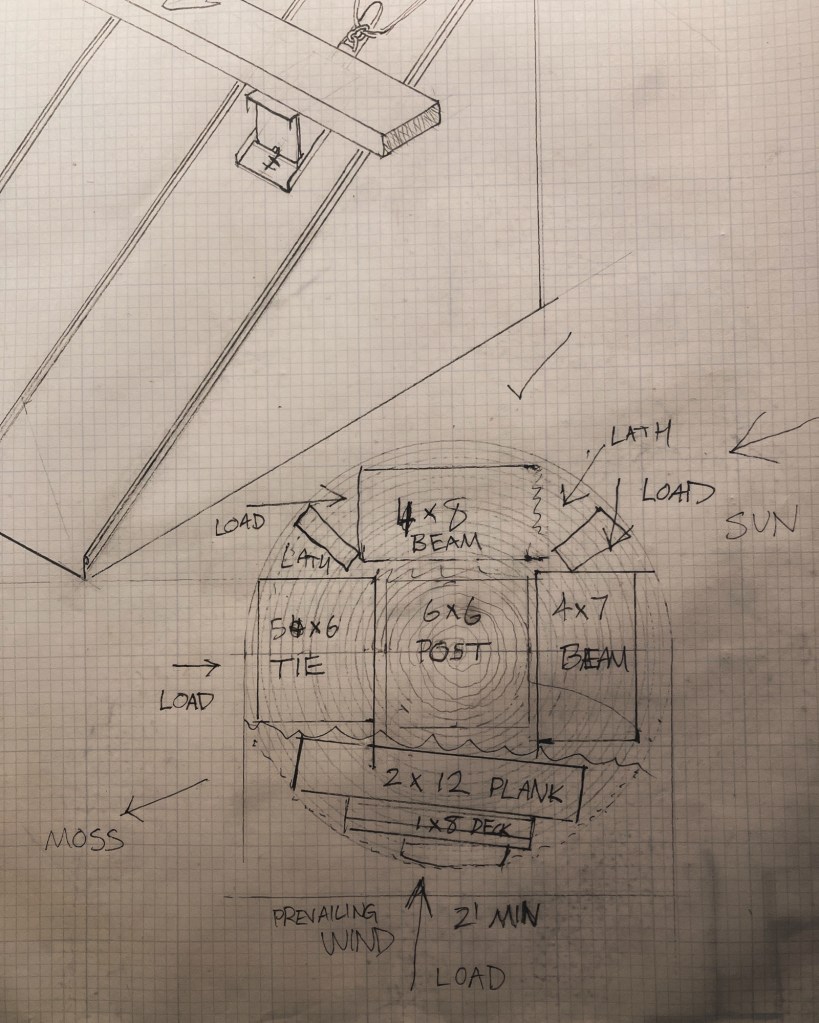

Rising up?

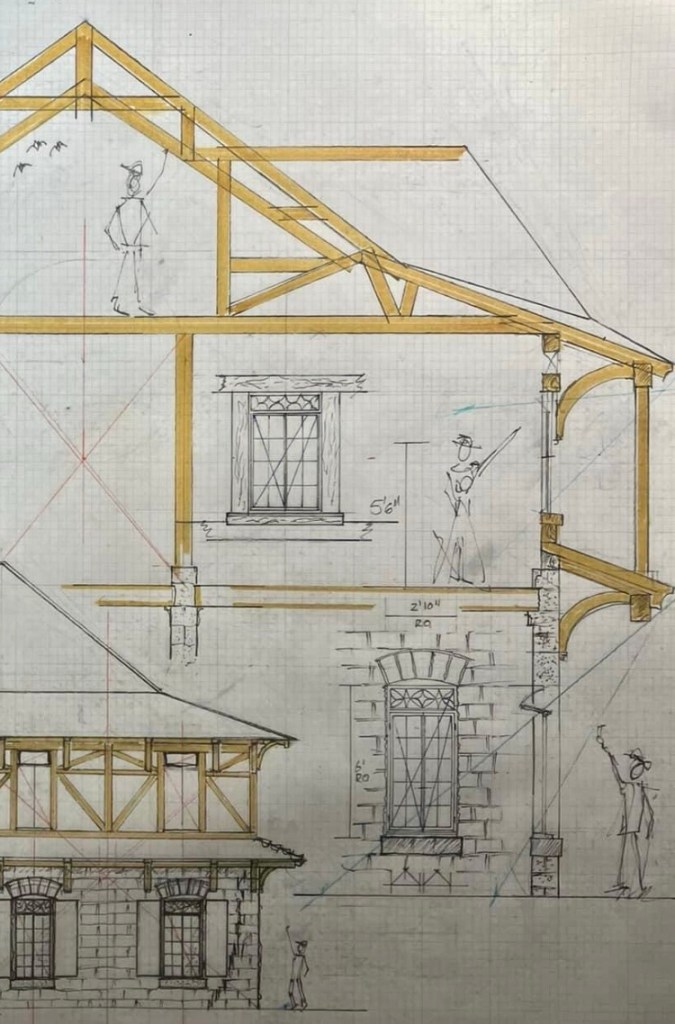

Gothic arch square groin vault, set on 7:12 pitch

let’s get caught up in class.

Ruff lads, window gals covered in sarco. You might look at all these stereotomy lessons we practice and think: “right, I’m not working on a cathedral, I’ll never use that” but we find intersecting forms needing the same pattern work all over construction. Inspired by this photo of a crudely mitered tile ridge cap, I decided to set off this task model: Gothic arch groin vault intersecting on 7:12 pitch.

*update: this is the third board. I’m using neubecker roof cutting bible as my main guide for the methods here. His book shows the development for the intersection of irregular hip intersecting a ridge….thats the first thing different about this, you have to draw the elongated form of the profile first (just like doing a crown mold on raking pediment) and it generates the plane for all the other cuts.

notes on the tedious debate of how to cut up a circle or generate an ellipse: it doesn’t matter. You can use tangents to find your centers and approximate with arcs that’s what they all did. long as you create the proper surface dev and hip oblique view as a checksum, you have your true length of the curve, and you have the coordinates in the oblique view, you have a full suite of information needed to generate the cut.

in real life when you cut on the material you will be using a spline to average the coordinates so it doesn’t matter how well you generated perfection with your circle dividing method.

In real life, on the most serious of stone cutting or timber shaping: I guarantee you, whatever “mazerole magic” they did on task model will be proved and checked with direct measure on the scribing floor. Those true lengths will become no longer theoretical but actual pieces of string or a spline. to find that curved surface it will be translated by the material properties of the tramel, the spline, and the action of the mechanic.

You must be logged in to post a comment.