I’m working on a new video for this. It’s a poor lesson because it doesn’t explain the WHY. First of all, nominal standards have been with us since the civil war and balloon framing boom. This was directly influenced by two things: the railroad and the green bar on the architect’s scale. The nominal dimensions of stick framing lumber are chosen to fit checksums within the 3/4 per inch scale.. even when boards were planed 7/8 or 1” that is still in the scale. All of this in the effort to use wood to compose cornice and stone building forms. Nicholson and some other “revivalist” 18th century treatises wrote whole books in the practice of specifying nominal dimensions from the desk which would translate to “shrunken” classical orders appropriate for wood.

That explains the shape… and size.

As for the quality and performance.. thats a whole book…. I would read “American canopy” if I were me. that’s all based on how the tree grew. And how it was chosen to be sawed. Plantations and monoculture logging produces poor timber products. The trees should mostly be left alone. Managed for biodiversity and maturity and harvested ethically for permanent building intents only.

Some notes on the actual forensics of each section. The 1920s tree is a young tree super fast growing, so it likely grew from clearcut. It would never be a good beam. It has a use at this age: They chose it for this purpose to be a stud, or vertical member of a superficial wall.

The 60s section is a slow growing tree, with a lot of integrity so likely logged from the west or north. But it was methodically production cut into a modular unit with no regard to grain direction or function. It could have been as well, beams or bearing planks, but was sold as a superficial stud.

The modern commodity lumber is made that way to “make line go up on a balance sheet.” It never should have been harvested.

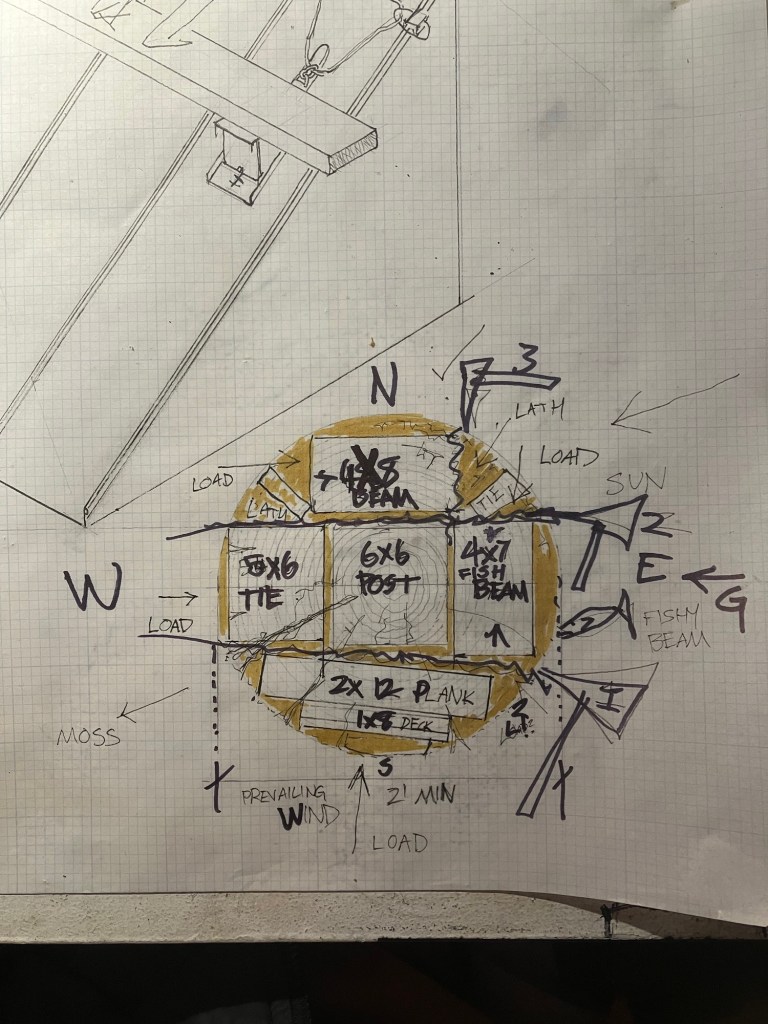

Wood from trees is judged accordingly: first you find a tree at least 2’ in diameter.. you look for the prevailing wind and spring line. You mark the tree on that axis and injure it to the sapwood. You come back the next season to Harvest it. Simple as.

How to grade cross sections for building units:

Beams: beams come from the spring line they have grain running parallel to the load. And they are growing towards the sun and crowned by the wind loads.

Post: post are the heartwood, they have compressive strength

Ties: ties are from the quarters. They have grain running at skews to the face. Great for cross joinery and tension.

Planks: planks are the strong back of the tree, the section which bent and stretched the most. Perpendicular to spring line with grain running in an arc across the load center.

You must be logged in to post a comment.