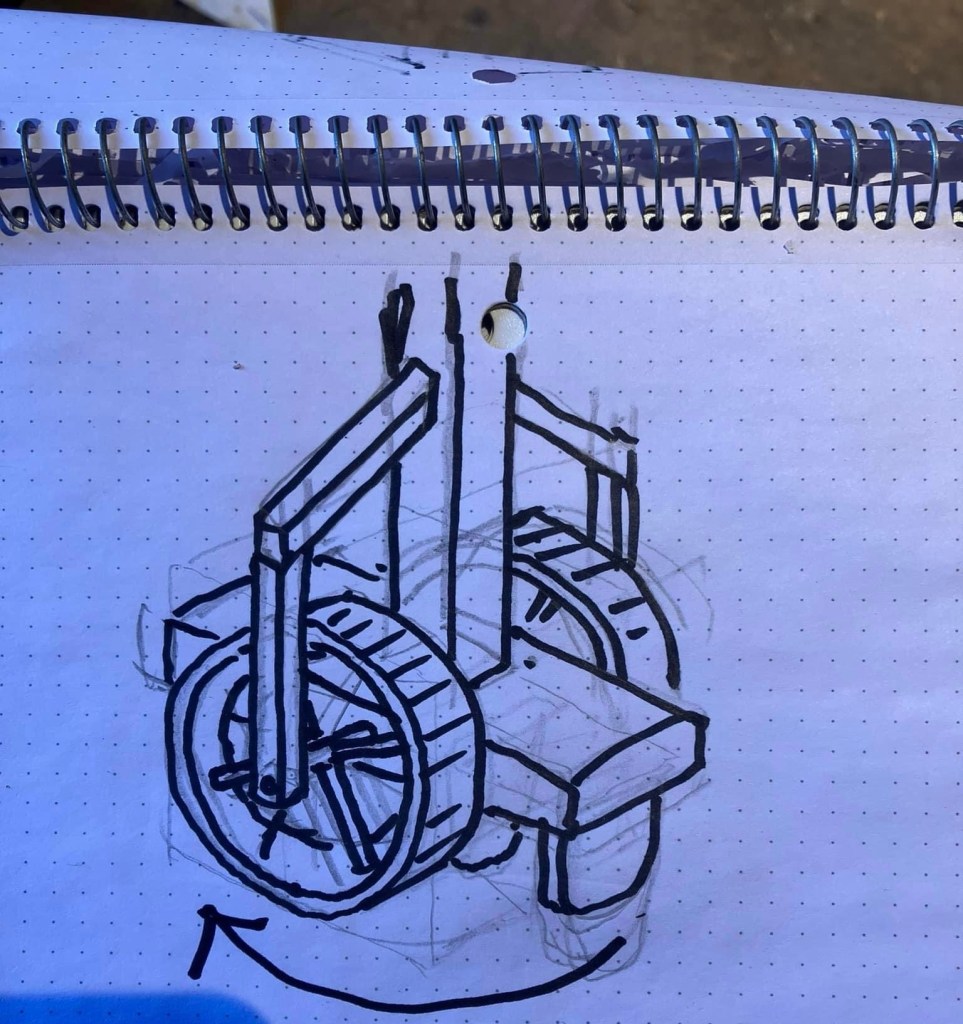

Joseph Aspdin’s 18th century Leeds was an infrastructure boom town due to the textile trade. Him: a bricklayer with no access to common stones found himself collecting precursor for cement by literally sweeping slaked lime dust (chalk) from bountiful waste products of road repairs. Collecting the stone road work-site dust by the 1/3 ton was enough work for anyone. But then: This dust by itself could not be fired in a kiln to make it alive again…. And who wants to work that hard anyway…. Instead he would make a slurry of the lime dust and clay heavy earth, pour it out and dry it, then those hard chunks of clay and lime could be fired much like any other. Once they were fired and ground down: you have your hydraulic cement.

Here’s a shocking thing maybe if you’re not a student of Nigel Copsey: this method was not new. It was used all thru the supposed “dark ages” all over the continent. Known as trass, water lime, ditch mortar, and wrongly known as “concrete”. It was used for floors, setting tiles, and water works. Nobody ever needed to rediscover Vitruvius in a monastery to know basic human building technology. The myths of “lost arts” are just that. Myths invented to sell class status and deskill labor.

It was pure scarcity that drove Aspdin away from craft practices, as his peers and competitors knew: the “Roman” method involved exploiting the hot mix reaction of quicklime combined with a hydraulic pozzolan dust to bind with the lime seeking air. The royal philosophers and scientist had access to experimental time. They classified pozzolans in vast tables and assigned numbers and latin names to every fucking stroke of the flask and flame down to the mole and calorie. Aspdin did not have access to much free stone to burn for quicklime, he was even arrested twice in his life for stealing stones from the roads themselves. Smeaton and Robert Scott Vicat and a whole murderers row of ghouls and industrialist will dance on the same subject.

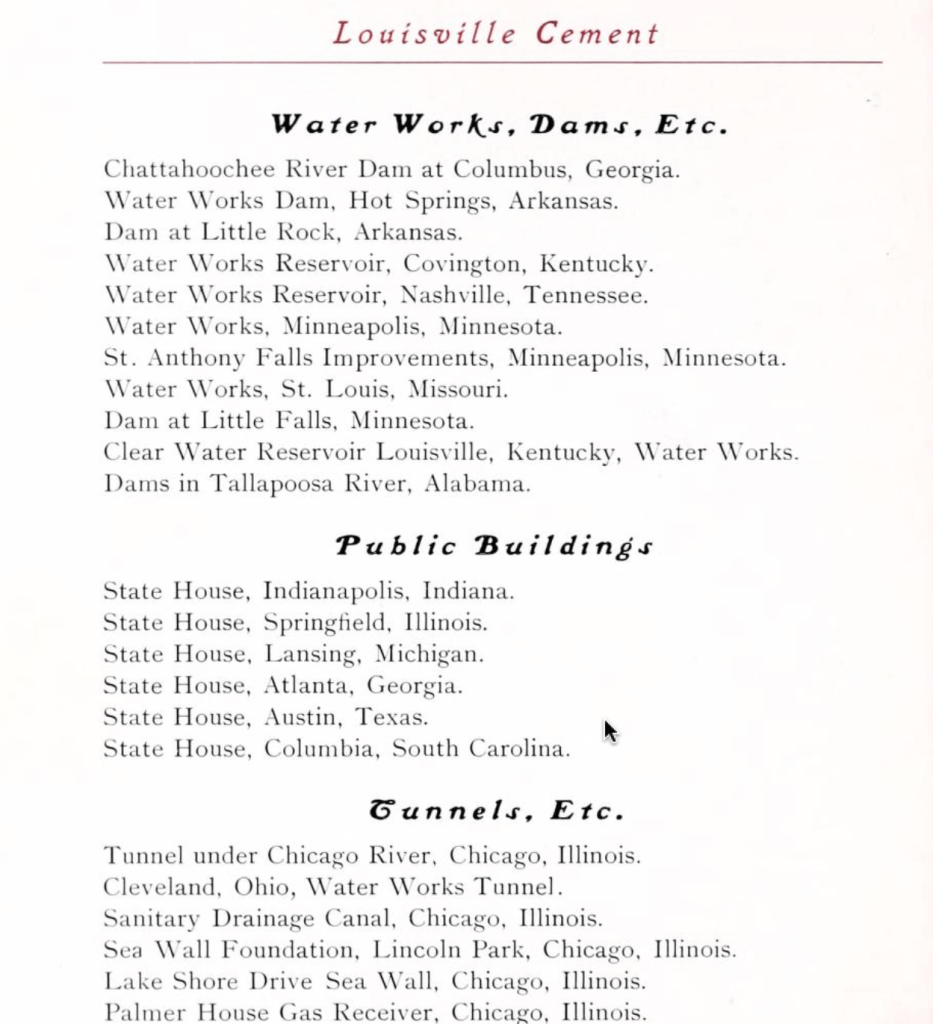

At the end of the research you find a bunch of myth making and grubstaking by the “winners” of building history to enclose upon and institutionalize what are two methods of action in chemistry involving just a few discrete steps and feedstocks. Mineral binders are only created and function two ways: either thru the quicklime /water reaction, and set thru exchanging air. Or thru exploiting the pozzolanic reaction and cold clay/calcine reaction, in the case of Portland cements.

You must be logged in to post a comment.