let’s get caught up in class.

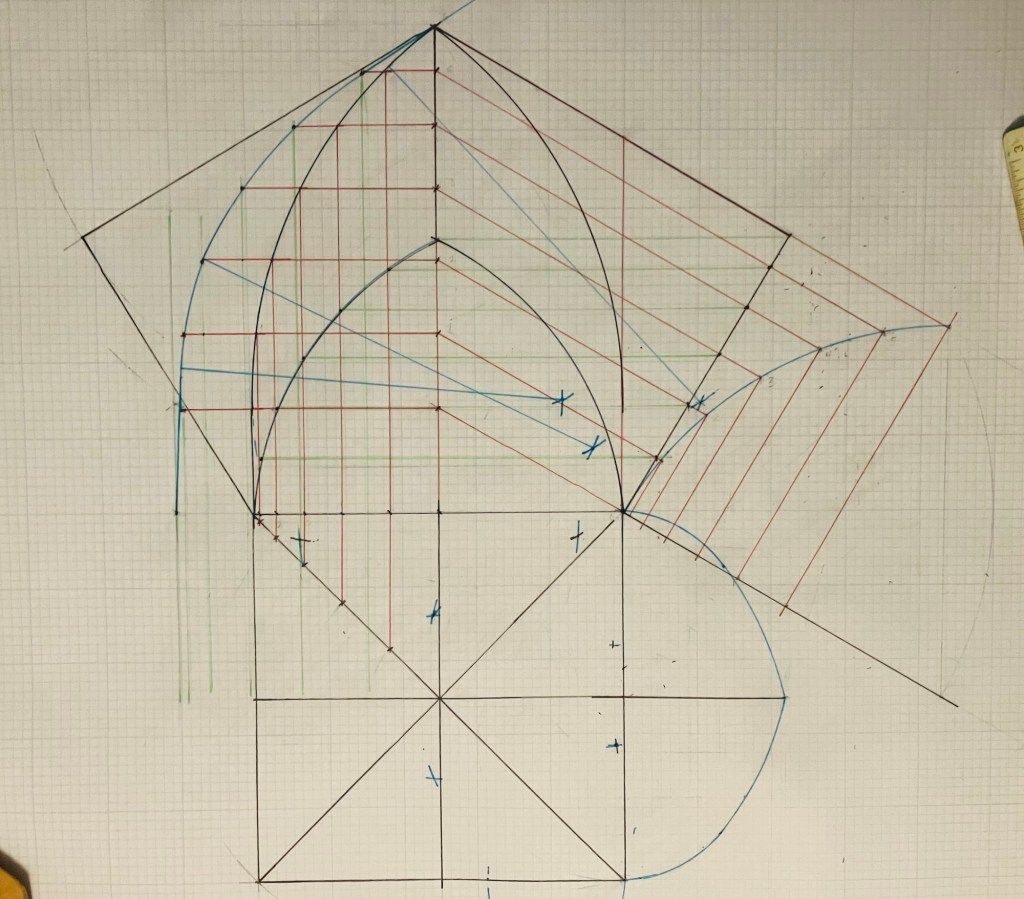

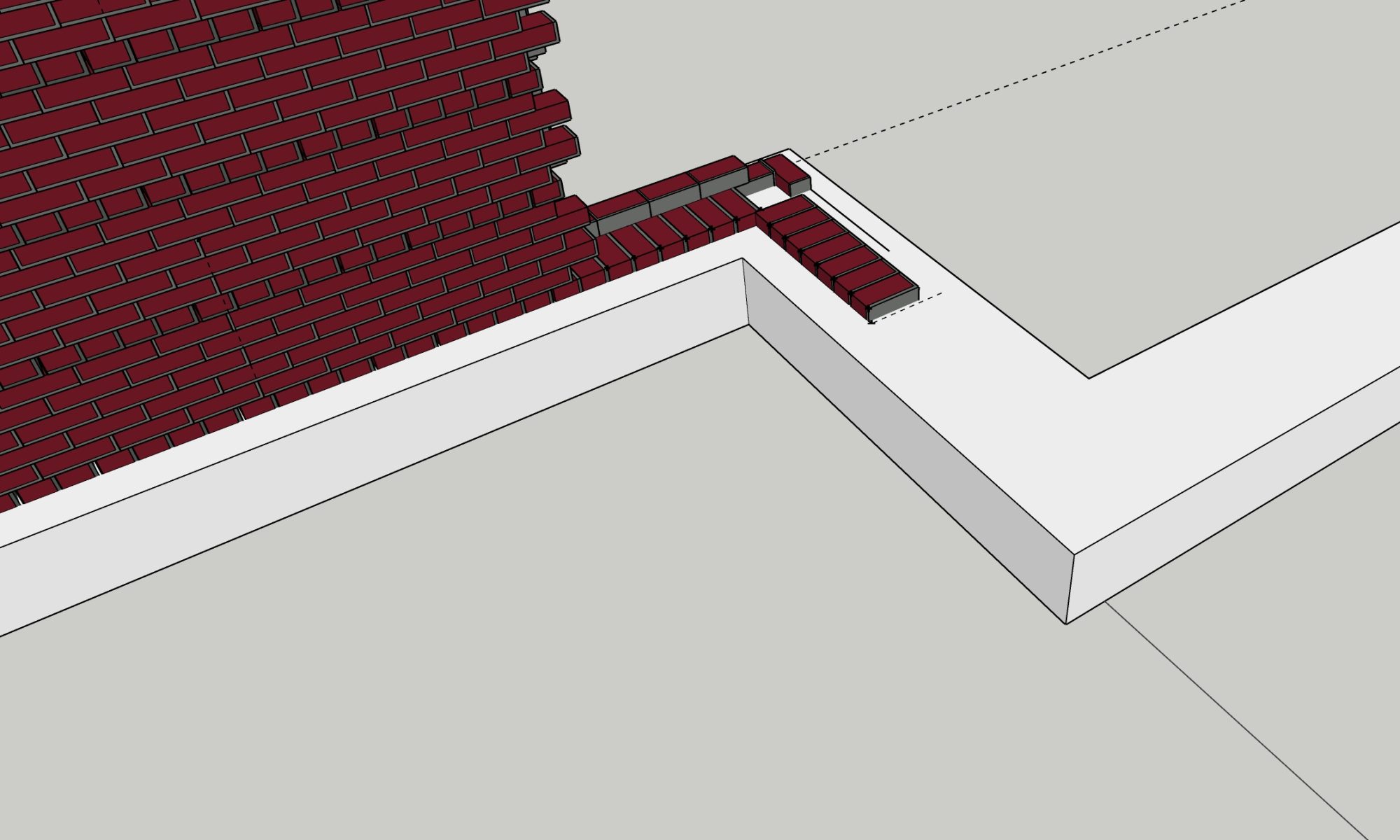

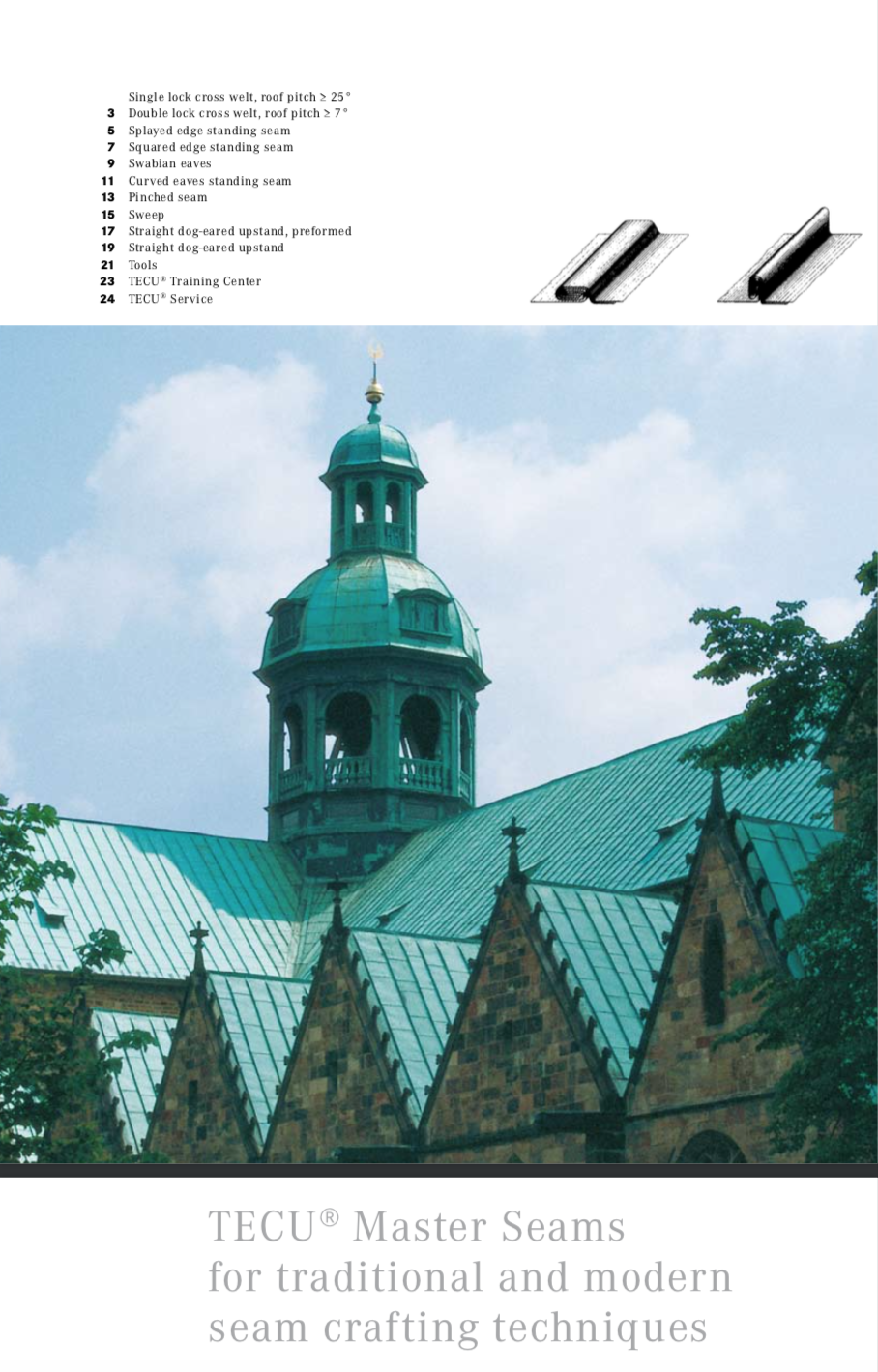

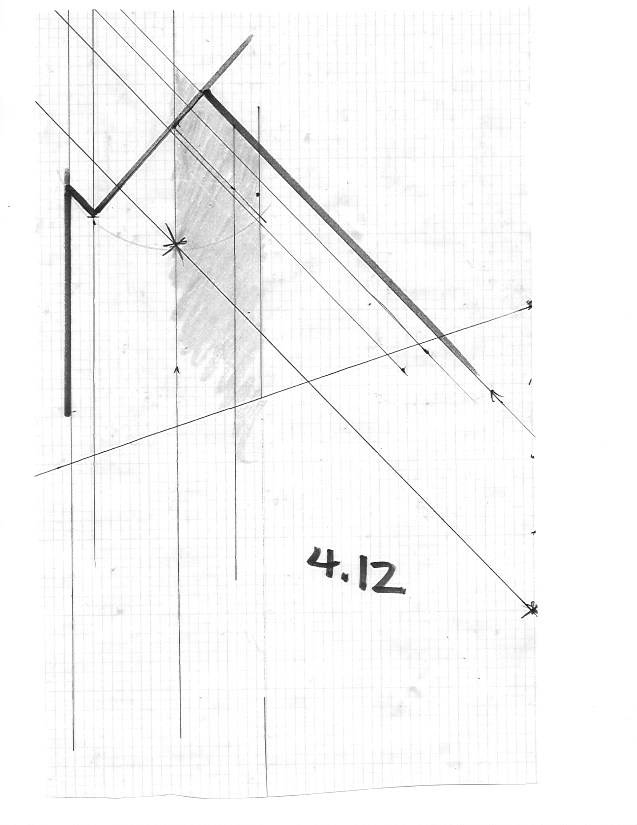

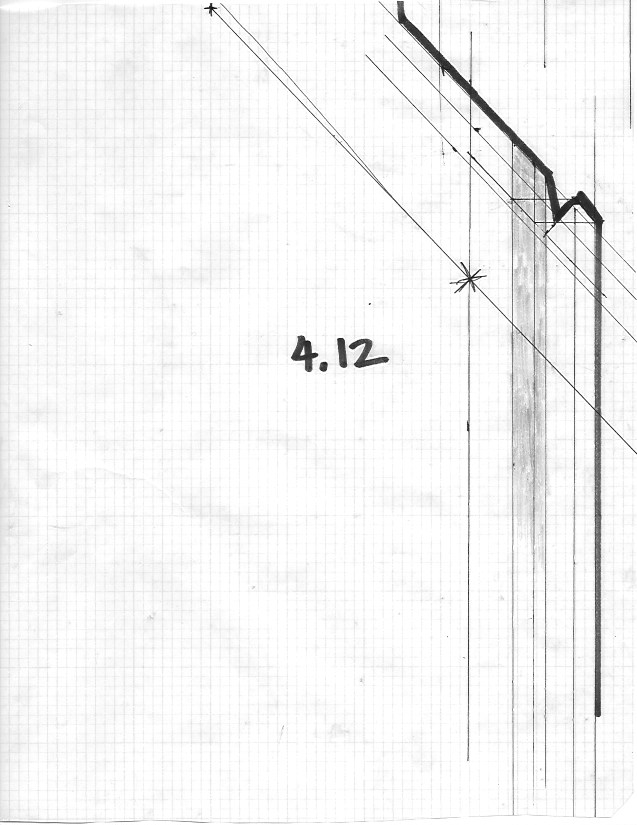

Ruff lads, window gals covered in sarco. You might look at all these stereotomy lessons we practice and think: “right, I’m not working on a cathedral, I’ll never use that” but we find intersecting forms needing the same pattern work all over construction. Inspired by this photo of a crudely mitered tile ridge cap, I decided to set off this task model: Gothic arch groin vault intersecting on 7:12 pitch.

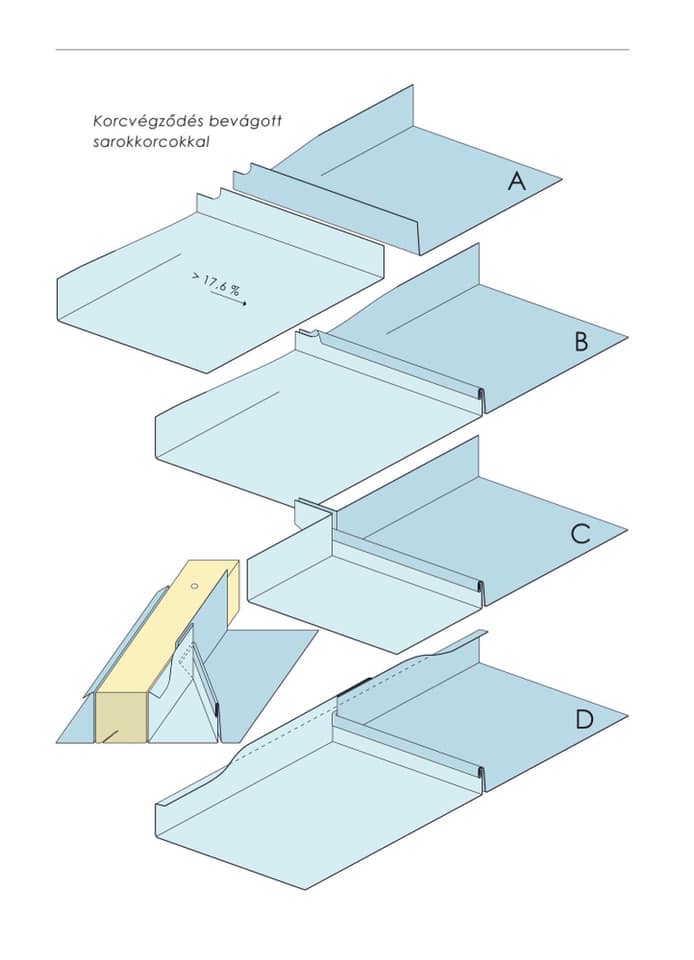

*update: this is the third board. I’m using neubecker roof cutting bible as my main guide for the methods here. His book shows the development for the intersection of irregular hip intersecting a ridge….thats the first thing different about this, you have to draw the elongated form of the profile first (just like doing a crown mold on raking pediment) and it generates the plane for all the other cuts.

notes on the tedious debate of how to cut up a circle or generate an ellipse: it doesn’t matter. You can use tangents to find your centers and approximate with arcs that’s what they all did. long as you create the proper surface dev and hip oblique view as a checksum, you have your true length of the curve, and you have the coordinates in the oblique view, you have a full suite of information needed to generate the cut.

in real life when you cut on the material you will be using a spline to average the coordinates so it doesn’t matter how well you generated perfection with your circle dividing method.

In real life, on the most serious of stone cutting or timber shaping: I guarantee you, whatever “mazerole magic” they did on task model will be proved and checked with direct measure on the scribing floor. Those true lengths will become no longer theoretical but actual pieces of string or a spline. to find that curved surface it will be translated by the material properties of the tramel, the spline, and the action of the mechanic.

You must be logged in to post a comment.