This is one of the first films I point people to, in order to show the difference between the american style of work and the traditional european style of copper or metal roofing. This is of special interest to those in charge of replacing historic copper roofing in america. If the goal is to re-create the look, and have durable successful results; it is best to avoid any american precedents and look for the preservation guidelines used by the expert guilds in europe for a baseline on how to conduct preservation work.

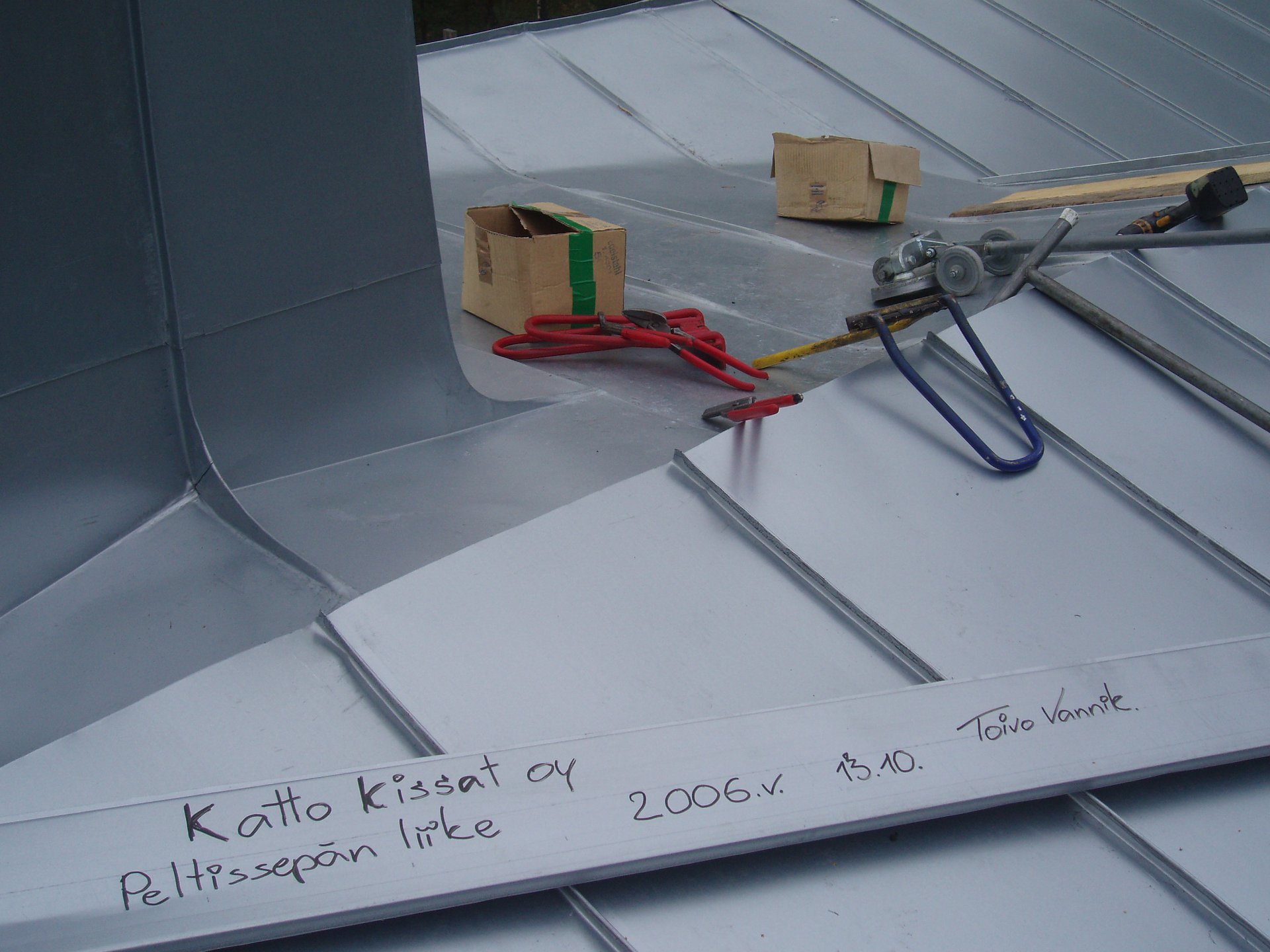

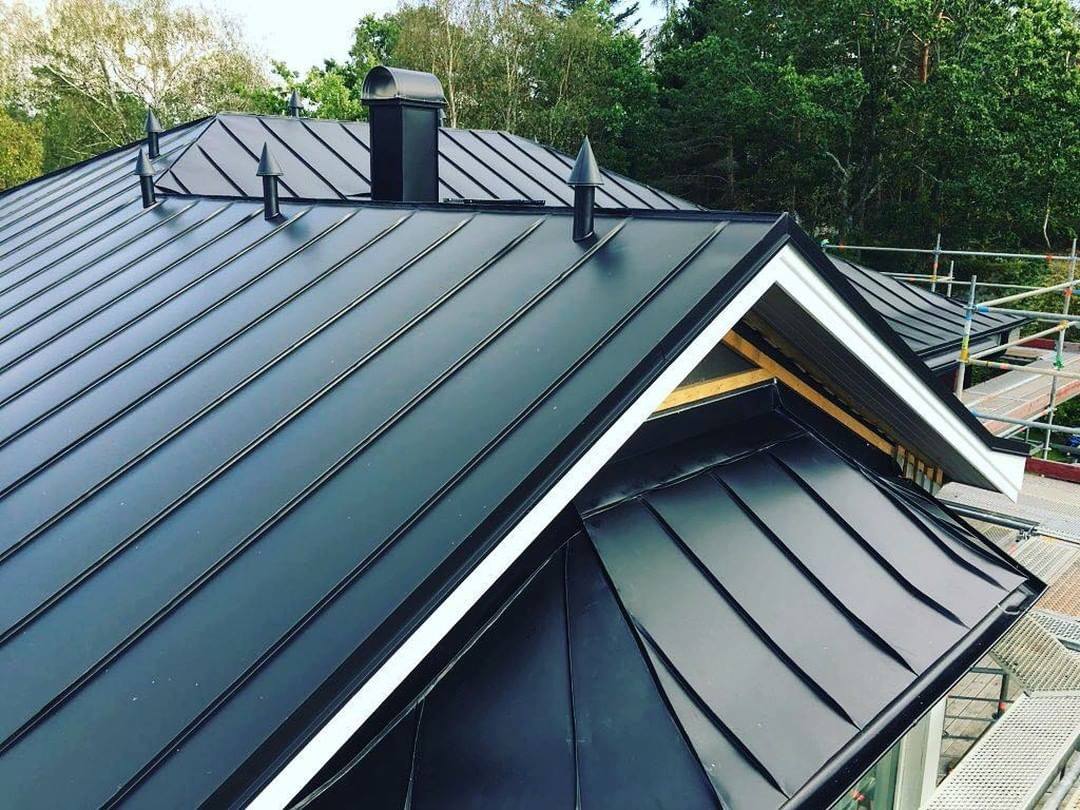

A great photo sequence that shows metal roofing joinery

It’s hard to write about joinery in plain english and properly translate the concepts that are important to understand. Most folds take several steps of planning and operation, they don’t look pretty during the process so it’s not very photogenic. It is also not so much fun to watch except for someone who is learning how to seam.

This is the biggest issue in America is education: There are so few roofers (even “historic” roofers) who understand how to seam, because the market is making money training people to do sub-par methods with caps, and sealant, and screws.

We don’t even understand fully the impact of what we lose by choosing to continue the “production” roofing methods. Mainly: lost wealth. This goes for the whole exterior of the house. We chose to put our wealth in the pockets of manufacturers: producing cheap windows, plastic and aluminum siding, and veneers. These products might give you a temporary “curb” appeal to the un-educated when they are new, but over time that initial investment will depreciate, and need “remodeling” in a generation or two. This means there’s a secondary market for disposable roofs, siding, and windows that you are locked into every 20-30 years.

The more prudent way to build wealth in a property is to restore the exterior (strip and paint if wood, tuck point with lime putty in brick). The windows can also be restored, and when properly restored with a storm window they function just as well as those plastic replacements which do not last.

Durable methods and materials provide a lasting true value that will not be chipped away at by future needs to repair or remodel.

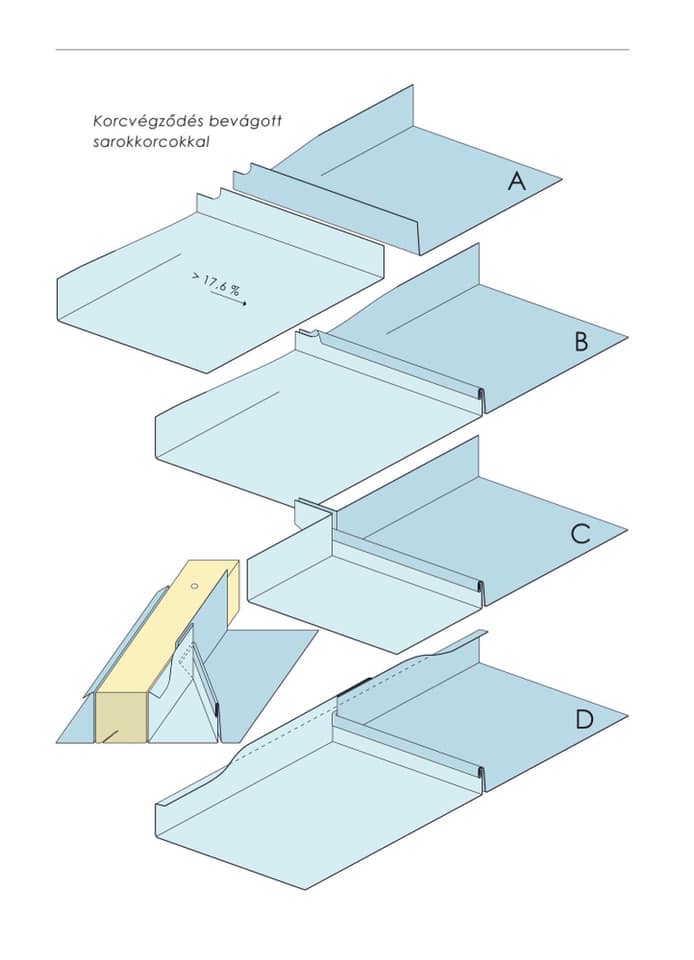

Metal roofing details: pinch seam

From Russia with love: metal roofing inspiration photo of the day

Compagnon Couvreur du Devoir

https://www.facebook.com/Compagnon-Couvreur-du-Devoir-793746534072924/

Compagnon Couvreur du Devoir, is a French roofing school. Promoting the best example of study for traditional metal roofing, fabrication, and design.

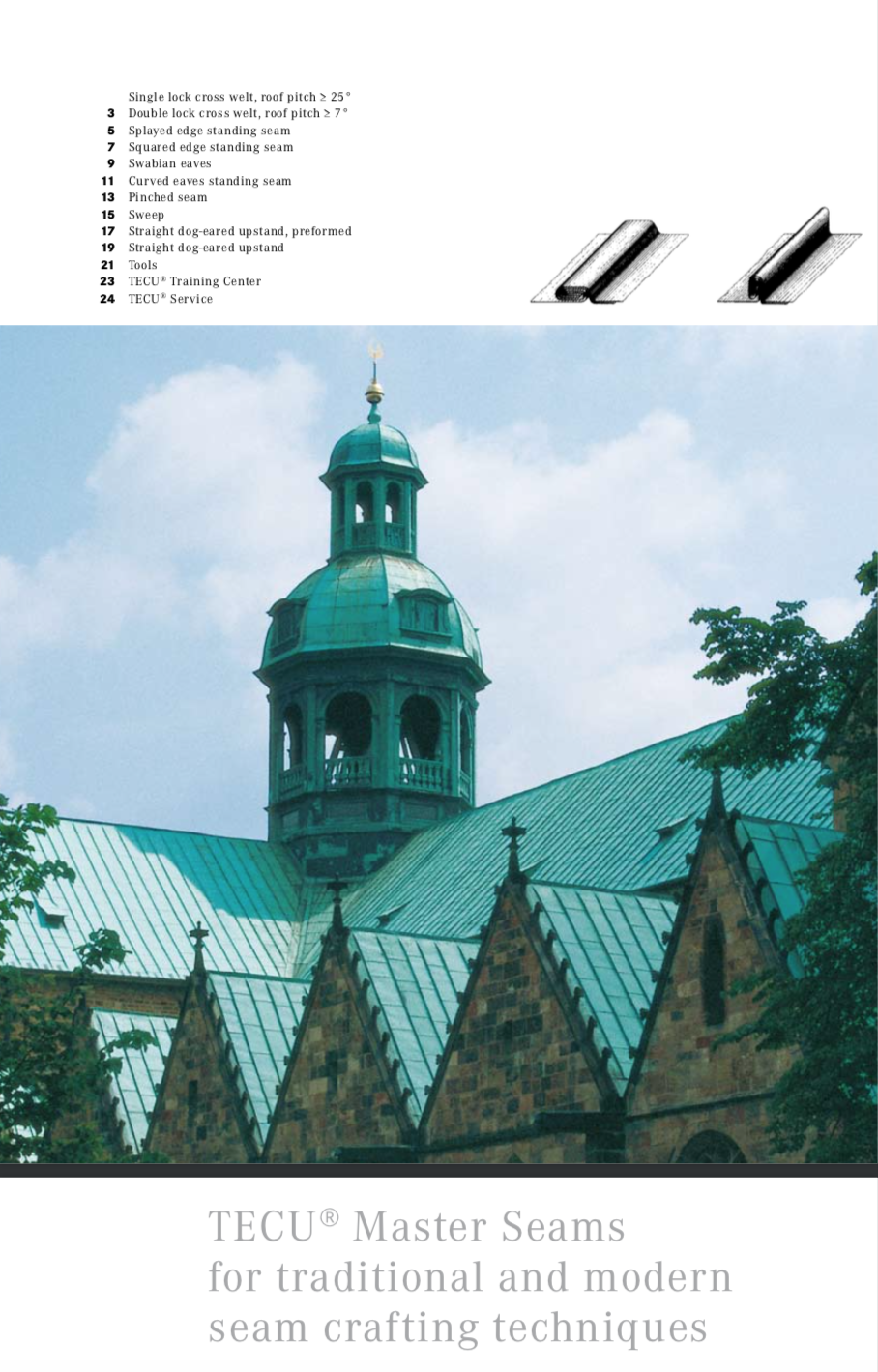

TECU Master Seams: a primer in metal roof seaming

There is very little information in english on traditional metal roofing. This is what prompted me to begin studying seaming, and publishing the metal roofing bible in 2018 after years of study and work in this field. I found all of the American resources lacking in this department, and most of the leaders in the field of historical roofing in America lacking in their knowledge of time-honored methods for folding and seaming. This short brochure is one of the few examples that show basic seaming techniques.

Although it does not offer instruction on how to create patterns for unique situations, it gives the reader the basics of the “knots” used to accomplish different details in metal roofing without cutting, soldering, or sealants. These techniques allow the roofing elements to be free-folded, and more importantly it allows the roof to be repairable in the future without disrupting the entire assembly. This is not possible with american flat-lock methods where pans are soldered together creating a monolith.

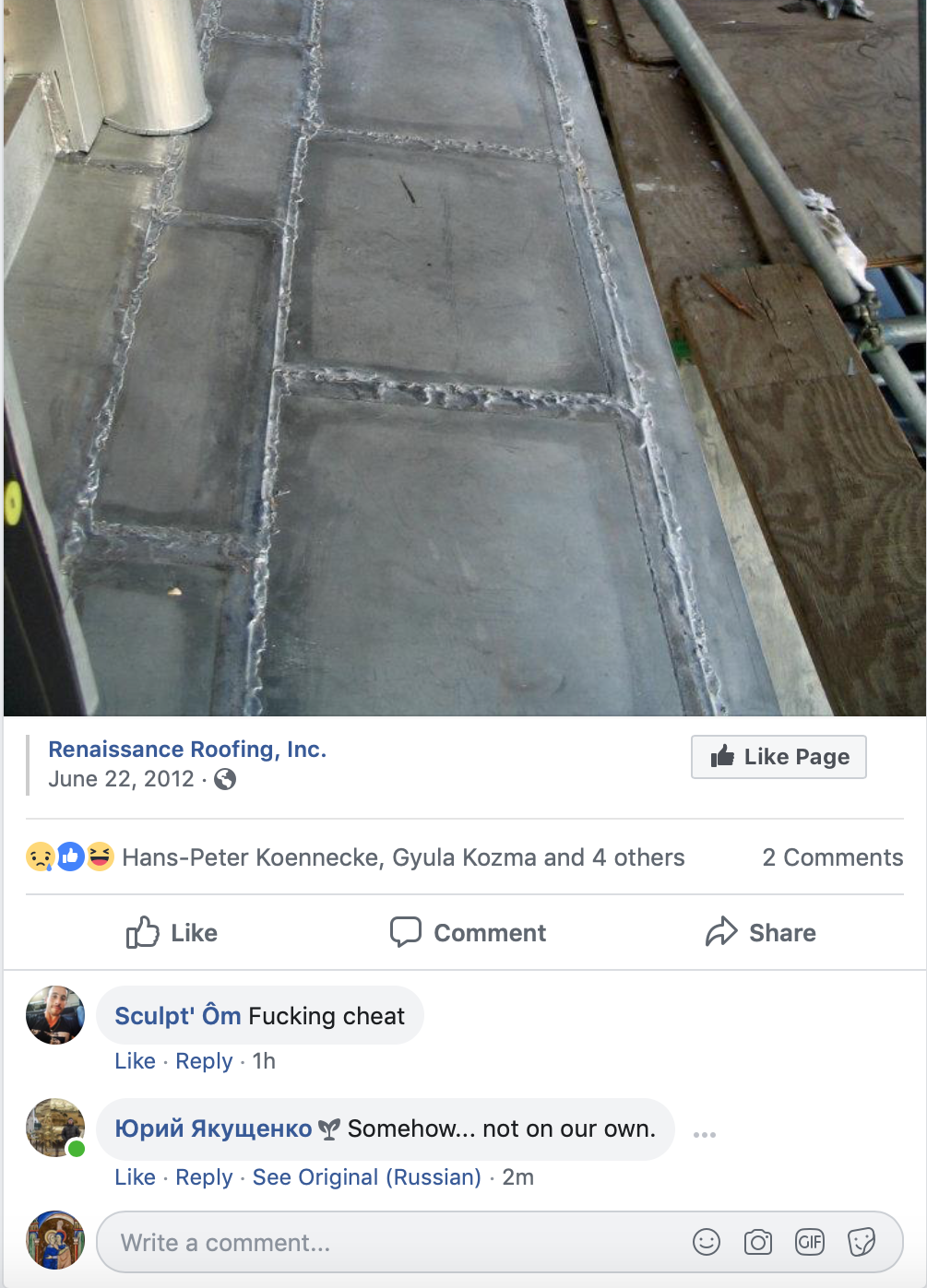

Renaissance Roofing, getting roasted.

In Europe, where the history and heritage of metal roofing comes from: flat lock was never used. It never even existed because they knew how to seam, and design their roofs properly.

They train for years to build actual permanent roofs, using methods they were adopted around the year 800 and are still in use today. Many of these european roofs have benchmarks for performing multiple centuries with no human intervention after the initial install.

Why is this important? It’s wasteful for one. Copper, and metal, and budgets on large public projects are not cheap in the US. The same amount of materials and labor could be applied with proper training and methods to produce much better results: results that will last centuries.

There is another issue: repairability. When you spend labor to slice up copper into “plates” fit them on the roof, and then solder them back together: you’e charged a whole bunch of money to put down a monolith, that will never be anything other than that. With free-seamed panels however if a repair of a single pan is ever required (bullets falling from the air, other trades mounting stuff and penetrating the roof at some point in it’s life… ) Then a single part of the roof can be repaired or re-worked without disturbing the entire assembly.

Historical references for copper roofing

While I was searching the Building Technology Heritage Library for a duty-free copy of Neubecker, I came across a new resource (to me).

The Anaconda Copper Mining Company, part of the Amalgamated Copper Company from 1899 to 1915,[1] was an American mining company. It was one of the largest trusts of the early 20th century and one of the largest mining companies in the world for much of the 20th century.[1]

https://en.wikipedia.org/wiki/Anaconda_Copper

The specs here are for 10oz copper, what they call “economy” roofing. I assume from the title, the marketing, and the specs it was offered less to promote permanent roofing, and more to sell copper. We would never use 10oz copper for a roof.

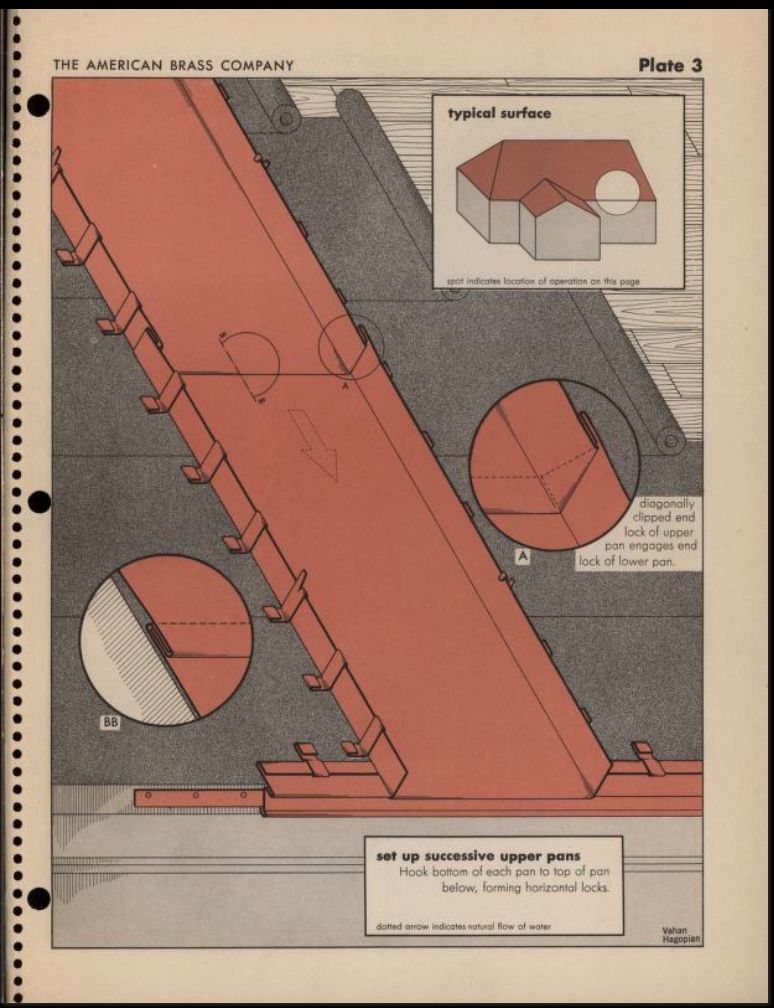

Right away, we are treated to incomplete information, and oversimplification… showing transverse seams. It gets worse on the next page…

Fixed clips can only be used on short rafters. (less than 28′). When you join the pans together with the field seam it creates columnar strength that essentially makes it a single pan. This is the hard lesson learned by those in europe who were tasked with replacing their own failing designs. The roof works against the fixed clips and eventually works them out, causing a wholesale failure over about 200 years. While this would be a decent life-cycle for most, we are striving for better and we now have the knowledge to do better. A general rule of thumb: if you are creating a copper roof that needs more than 2 10′ pans, incorporate expansion clips. Further: the roof needs a fixed point in the middle, for low pitches, and higher up the roof depending on pitch. This is to account for “critical loading” where the weight of the roof itself starts to bear on the clips and fasteners as the pitch increases. For a steep roof: the fixed clips are placed almost near the top, with expansion clips below.

So what’s wrong with this? Several things: the rules dictating the use of transverse seams are completely reliant on the pitch, and overflow/backflow conditions. Further they don’t demonstrate what the rules are for creating the notch. This is covered with more clarity in a modern resource:

Even with these rules of thumb, it’s important to realize other factors can determine the use of a wide-notch transverse seam at low pitch.. It can only be used in un-obstructed field where there is no risk of overflow.

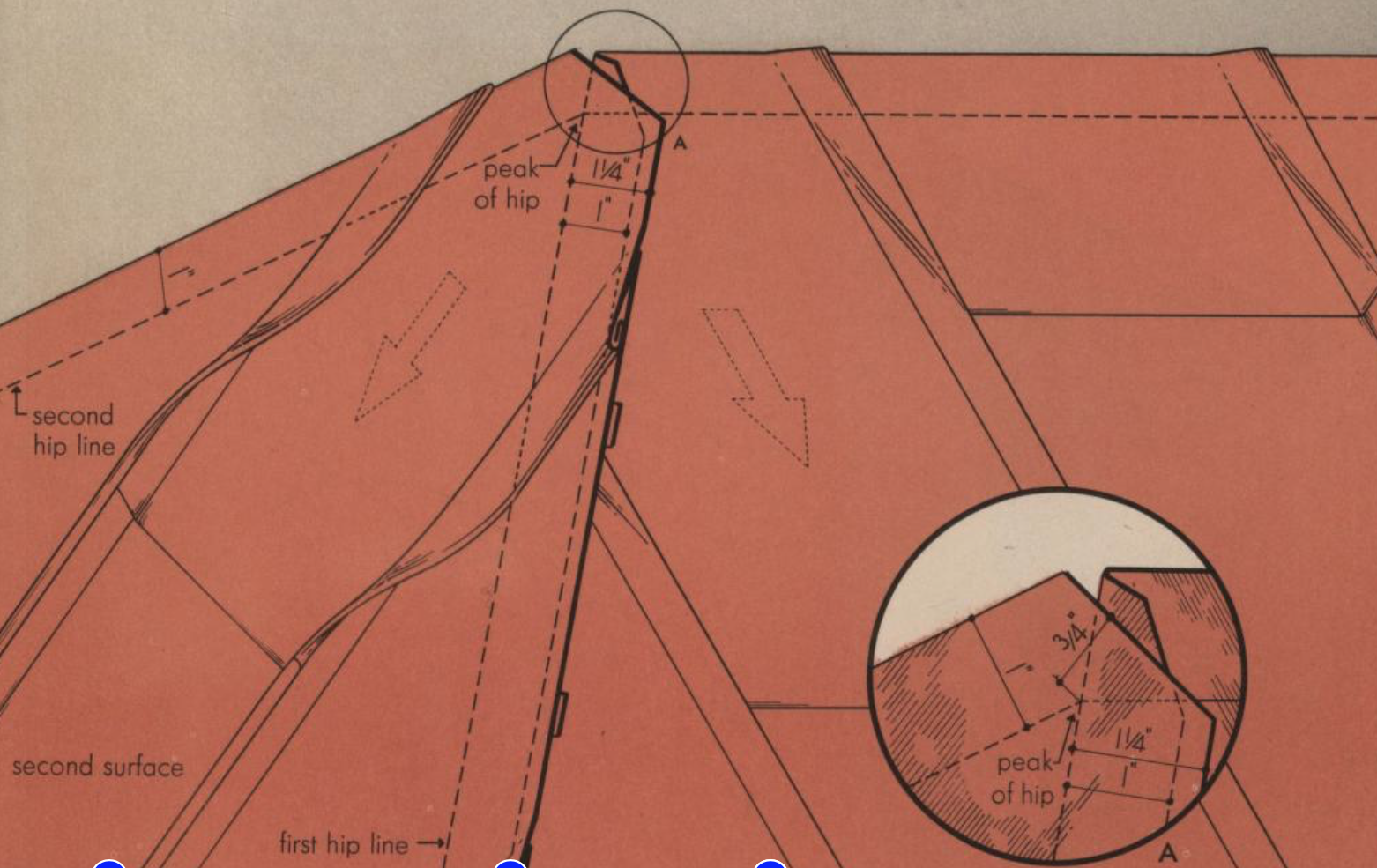

A few pages later, we see some very simple hip “instructions” showing dead-cut full seams with no notching. It was possible to fold a light-gauge steel roof with no notching to the pattern, but it’s not recommended. Anyone who has attempted to fold 6-8 layers in copper knows this.

While I was excited to see a reference showing the actual folding of hips and ridges, this ultimately does not help the installer create a permanent assembly as it could be with the proper planning, and care to joinery. It is better than Neubecker’s treatment of standing seam, but only gets us about halfway there.

This goes to demonstrate the main issue with knowledge of metal roofing in America. We assume that historically: they knew what they were doing but our references compared to similar work and knowledge from the old world shows this is not the case.

Spengler TV

Spengler is the official trade name in Germany (and maybe some other countries) for metal roofing. I’ve watched this channel grow up on Youtube, and wow they have added a lot of content! Metal roofing and standing seam, are codified by law there. This means everything last longer, there are fewer repair and maintenance cost. And on the market side: it means everyone has to play by the same rules, much like a bar or medical association. They study and master the techniques in secondary school. This is miles above “on the job” training, or even union training here in the US. Since union training is still focused more on meeting the “market” production demands.

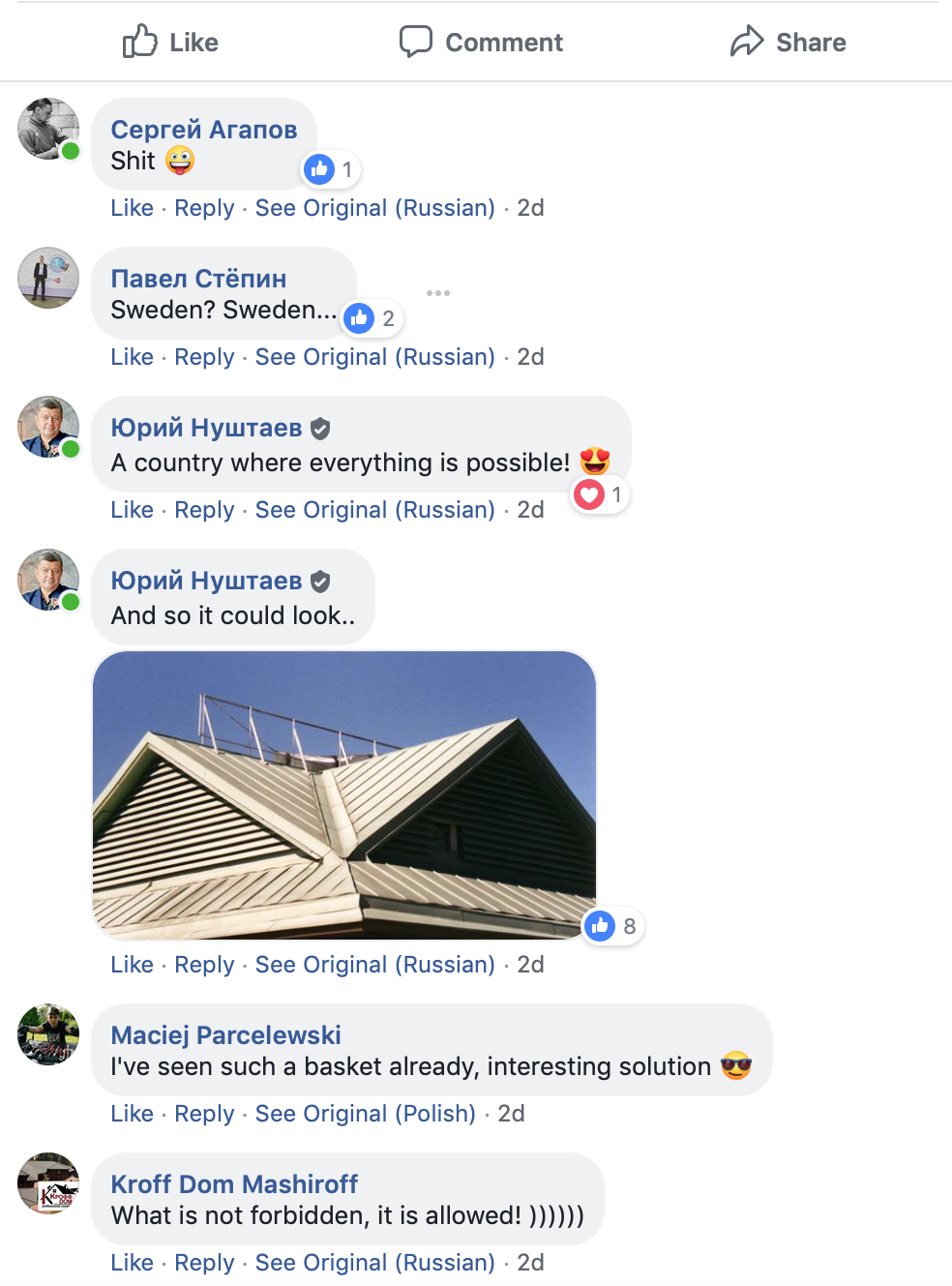

КИЯНКА

This forum, on FB is absolutely one of the best sources for information and example photos for permanent, standing seam roofing. We rely on the translator service as almost nobody speaks english. Back in 2012, when I was studying folding and joinery techniques (with zero online resources in english) I used to pull the text one-by-one from PHP forums and paste into google translate. This is so much better as we can actually communicate; although it is somewhat broken.

This photo shows a really interesting valley concept, and the debate ensues… What is so unique and showy about this approach is that one whole side of the field had to be installed, and turned up. When the opposing side was installed: since the seams have to run in to and past the valley, it means they had to deform every field seam down, and lay them all over all the way up, so the pans would sit flush on the field. This is working blind. After that, they would have to close all of the connecting seams, and dress it down to fold the valley.

You must be logged in to post a comment.