Whenever in history there was a shortage of building materials, creativity was needed and often a circular approach was the answer. In the 16th century, the French Philibert de l’Orme invented a new building method, the so-called “à petit bois”, in which large roof spans were made of small pieces of wood. I was struck by the beauty and the genius who designed it, visiting the barn of the chateau Maurier in France. This method could be one of the first intended circular construction solutions ?

France in the 16th century was a place and a time where big wooden beams were expensive and barely available (*). The classical way of building, with big wooden trusses, was not an option anymore. In his book «Nouvelles Inventions Pour Bien Bastir Et a Petits Fraiz» (Ed.1561), Philibert de l’Orme described an alternative way of building, which is as simple as effective.

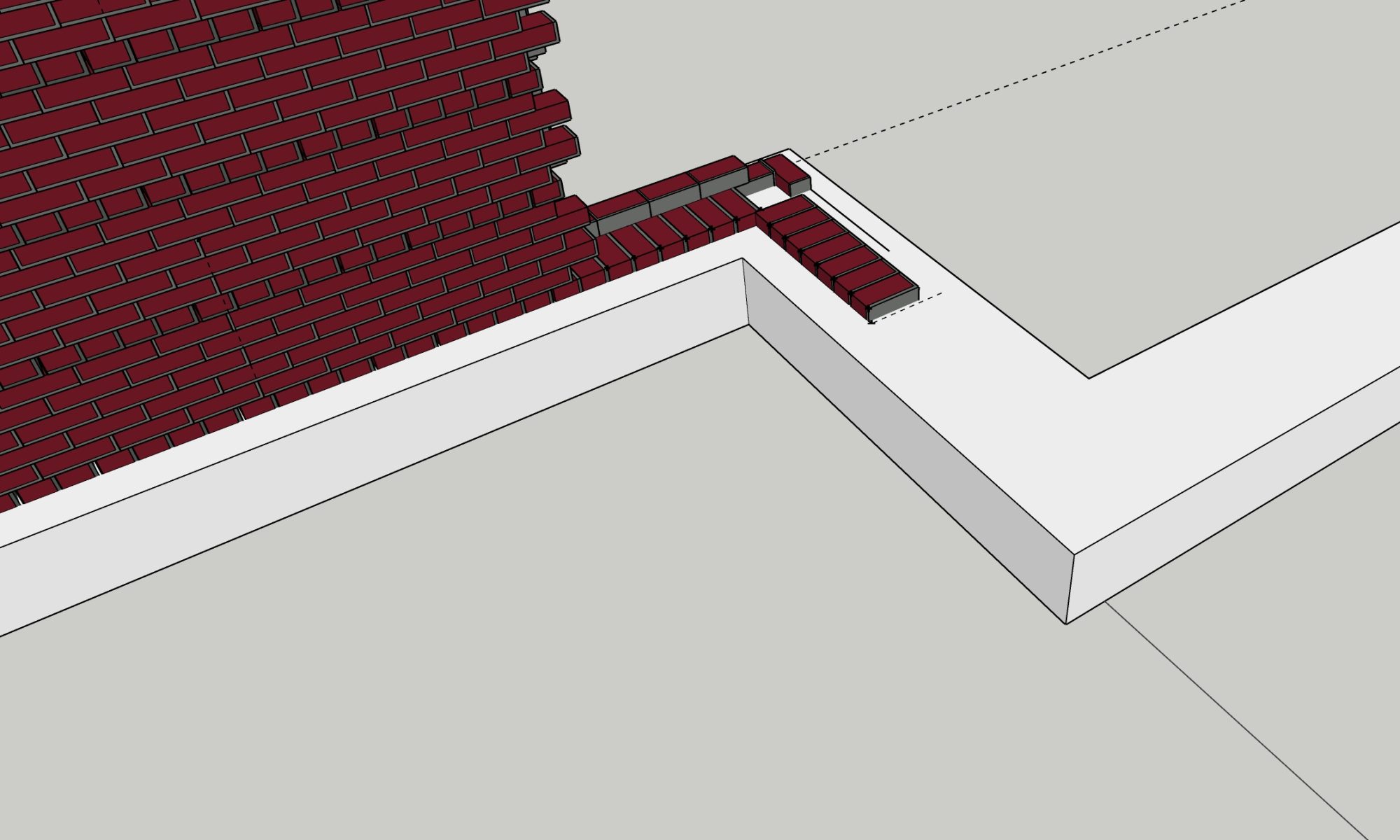

With still affordable and available short wooden battens, about 1.30m long, he managed to make huge roof spans, by a very clever “meccano” method of “nailing” them together with dowels. This is a solution which can be seen as the precursor of modern glulam beams. Scarcity of materials as a driver for a circular economy.

Only two types of these battens were needed. Prefabrication of thousand exactly similar wooden pieces could take place in a very cost-efficient way. Modularity as a characteristic of a circular economy.

Illustration : Ph. De l’ Orme, dans «Nouvelles Inventions Pour Bien Bastir Et a Petits Fraiz» (Ed.1561) ; only two types of prefabricated battens are used.

Whenever a piece of wood was infected or broken, it could easily be replaced by a similar one, without the need of breaking down a whole structure. Interchangeability and reversible joints as a characteristic of a circular economy.

Above all, by designing the roof in a form of an arch, or in the form of two arches (like an inverted boat-hull), the material is optimally used. There is no material underperforming its maximal strength. A clever design and a dematerialisation are the first steps in, and the key-factors of a circular economy.

Even though aesthetics were surely not considered to be important in the design of barn roofs in the 16th century, they do play a role in giving a building or building materials multiple lives. And this is what circularity in the design and construction is about.

The barn of Chateau de Maurier, Fontaine-Saint-Martin (F) , architect unknown, inspired by Philibert de l’ Orme, photo : BLIEBERG Architects of a circular economy

Philibert de l’Orme, once a famous architect on the court of Henri II (who designed e.g. the ballroom of the castle of Fontainebleau), fell in disgrace after the death of the monarch. Two years later, he wrote an appendix to his written chef-d’œuvre in which he gave a solution for people who could not afford expensive methods of building.

Kris Blykers, BLIEBERG architects of a circular economy http://www.blieberg.eu

You must be logged in to post a comment.