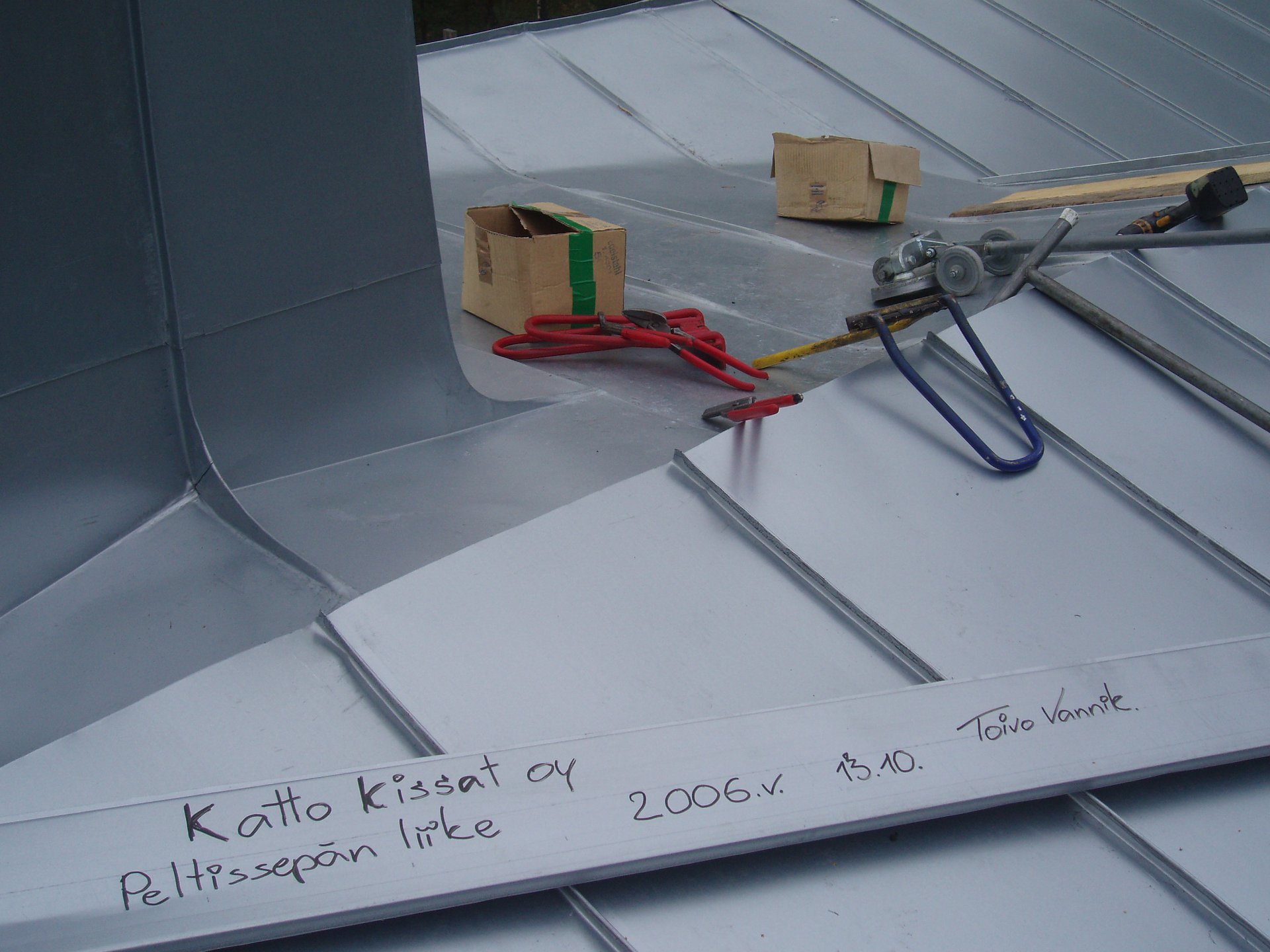

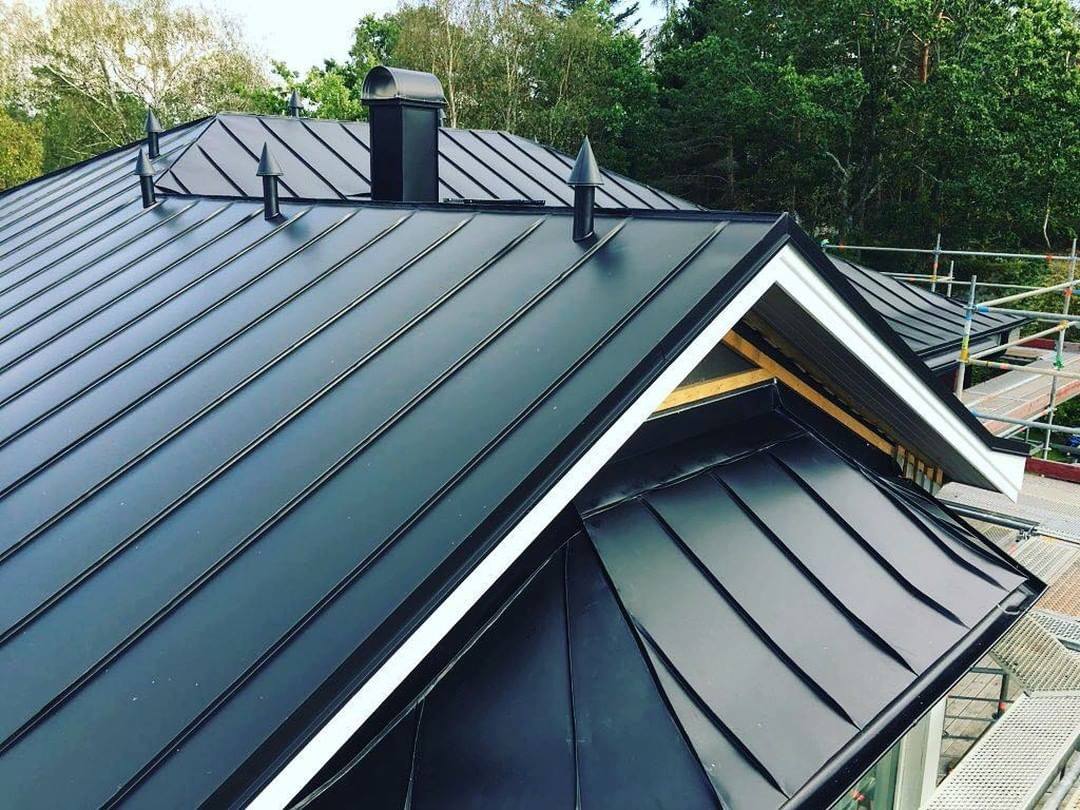

Great example of a classic metal roof with mechanical lock standing seam, and fully seam details on all the joinery. Even with the cap, it features full seaming in the valley and ridge transitions. This makes all the difference in longevity.

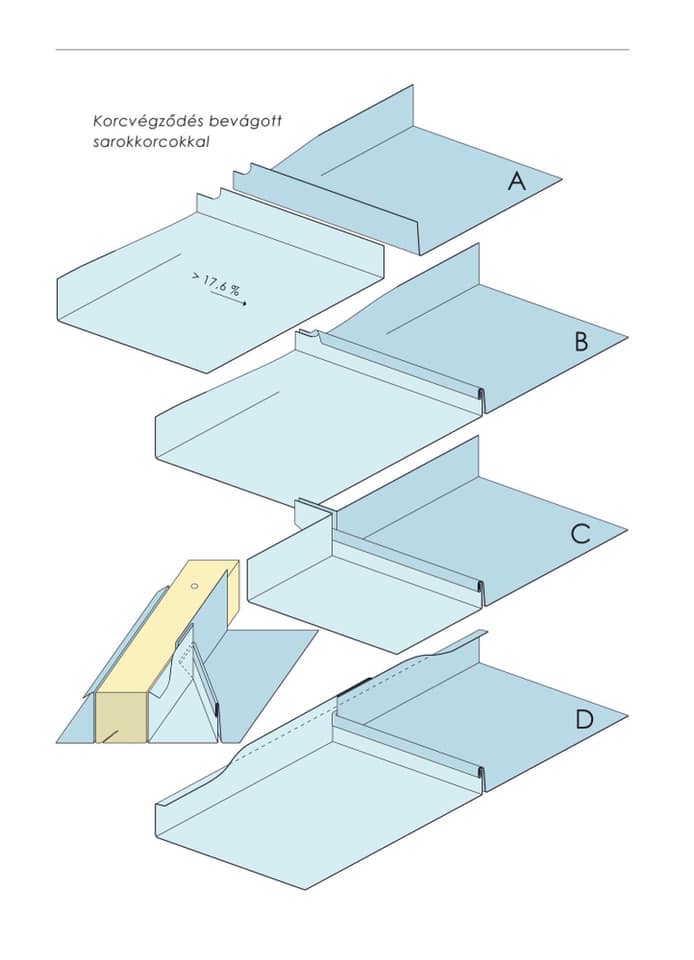

A great photo sequence that shows metal roofing joinery

It’s hard to write about joinery in plain english and properly translate the concepts that are important to understand. Most folds take several steps of planning and operation, they don’t look pretty during the process so it’s not very photogenic. It is also not so much fun to watch except for someone who is learning how to seam.

This is the biggest issue in America is education: There are so few roofers (even “historic” roofers) who understand how to seam, because the market is making money training people to do sub-par methods with caps, and sealant, and screws.

We don’t even understand fully the impact of what we lose by choosing to continue the “production” roofing methods. Mainly: lost wealth. This goes for the whole exterior of the house. We chose to put our wealth in the pockets of manufacturers: producing cheap windows, plastic and aluminum siding, and veneers. These products might give you a temporary “curb” appeal to the un-educated when they are new, but over time that initial investment will depreciate, and need “remodeling” in a generation or two. This means there’s a secondary market for disposable roofs, siding, and windows that you are locked into every 20-30 years.

The more prudent way to build wealth in a property is to restore the exterior (strip and paint if wood, tuck point with lime putty in brick). The windows can also be restored, and when properly restored with a storm window they function just as well as those plastic replacements which do not last.

Durable methods and materials provide a lasting true value that will not be chipped away at by future needs to repair or remodel.

The joys of metal cladding

We have a terrible history of metal siding or cladding here in the states… Mostly because of poor aluminum and plastic products and no thought to design or longevity. These projects from overseas show what is possible with just a little bit of training: and even a cheap material like coated steel can give you great results like this:

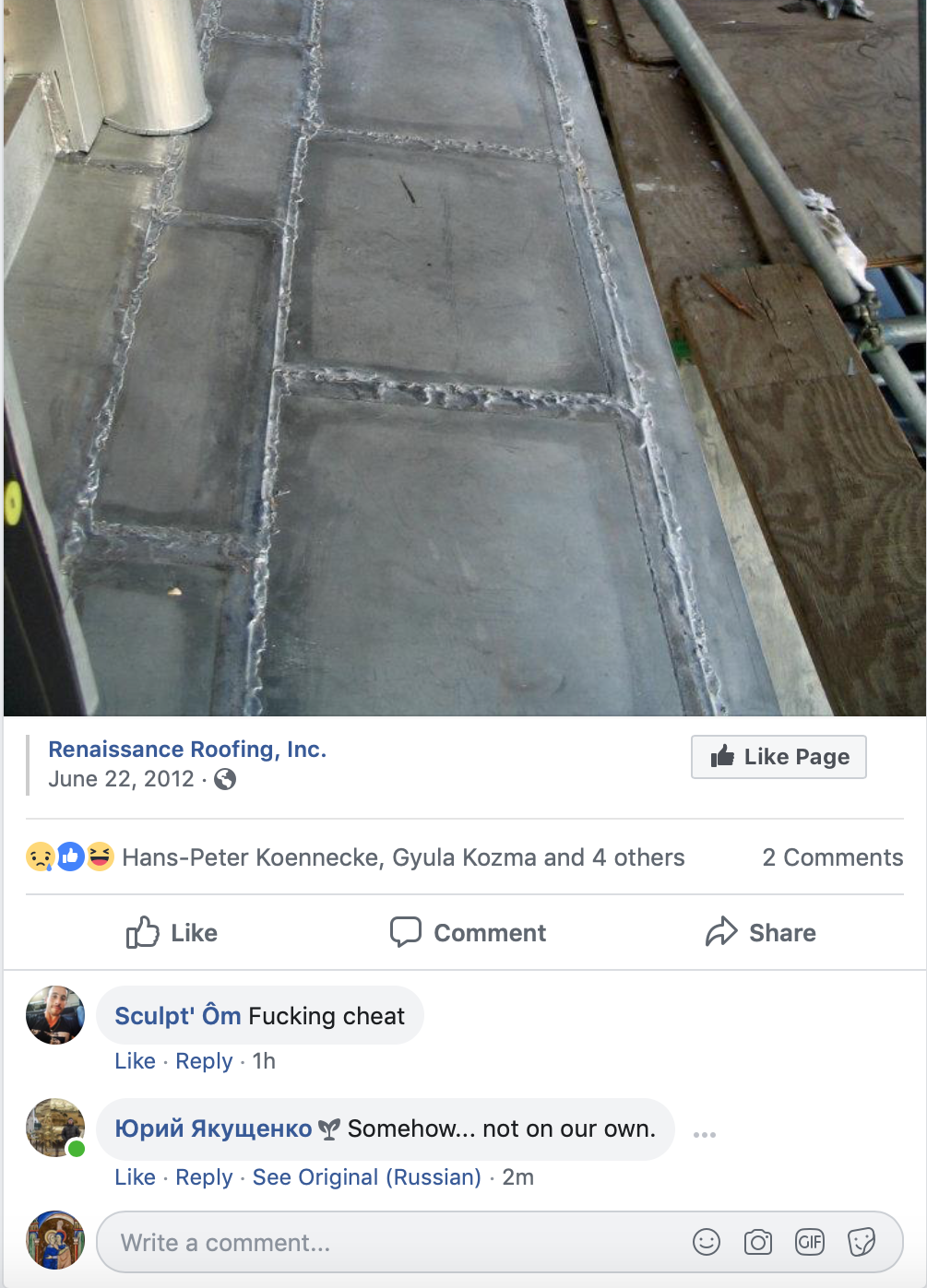

Metal roofing details: pinch seam

A formula for true value in building.

The only suitable building materials:

- Lime putty

- Sand

- Brick

- Stone

- Noble timber

- Slate

- Tile

- Copper

The only suitable methods for walls/frames:

- Timber frame with joinery

- Mass wall in brick or stone, timber frame roof

- Other folk methods with established record of lasting 500 plus years

The only suitable methods for roofs:

- Slate or Tile, with seamed flashing

- Standing seam with fully seamed joinery

The only suitable intent:

- extreme life cycle

- place making

This formula, if followed; will build generational wealth for the property holder, and lasting value for the places created by building as such.

With all our power equipment it is more accessible than it was in the past. Less labor than anyone building pre-oil ever had to endure.

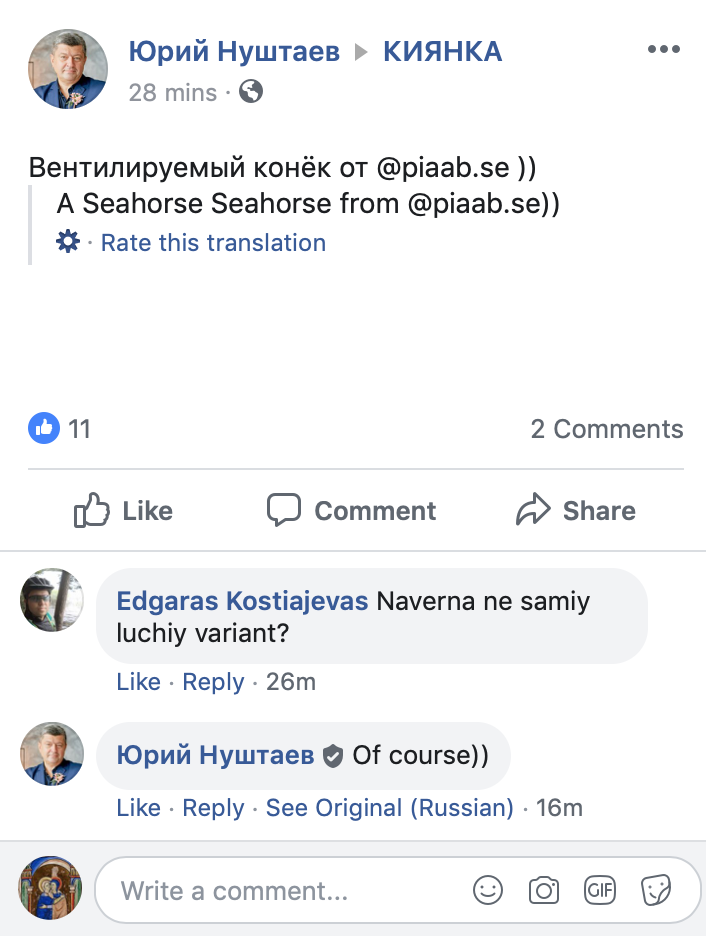

From Russia with love: metal roofing inspiration photo of the day

Compagnon Couvreur du Devoir

https://www.facebook.com/Compagnon-Couvreur-du-Devoir-793746534072924/

Compagnon Couvreur du Devoir, is a French roofing school. Promoting the best example of study for traditional metal roofing, fabrication, and design.

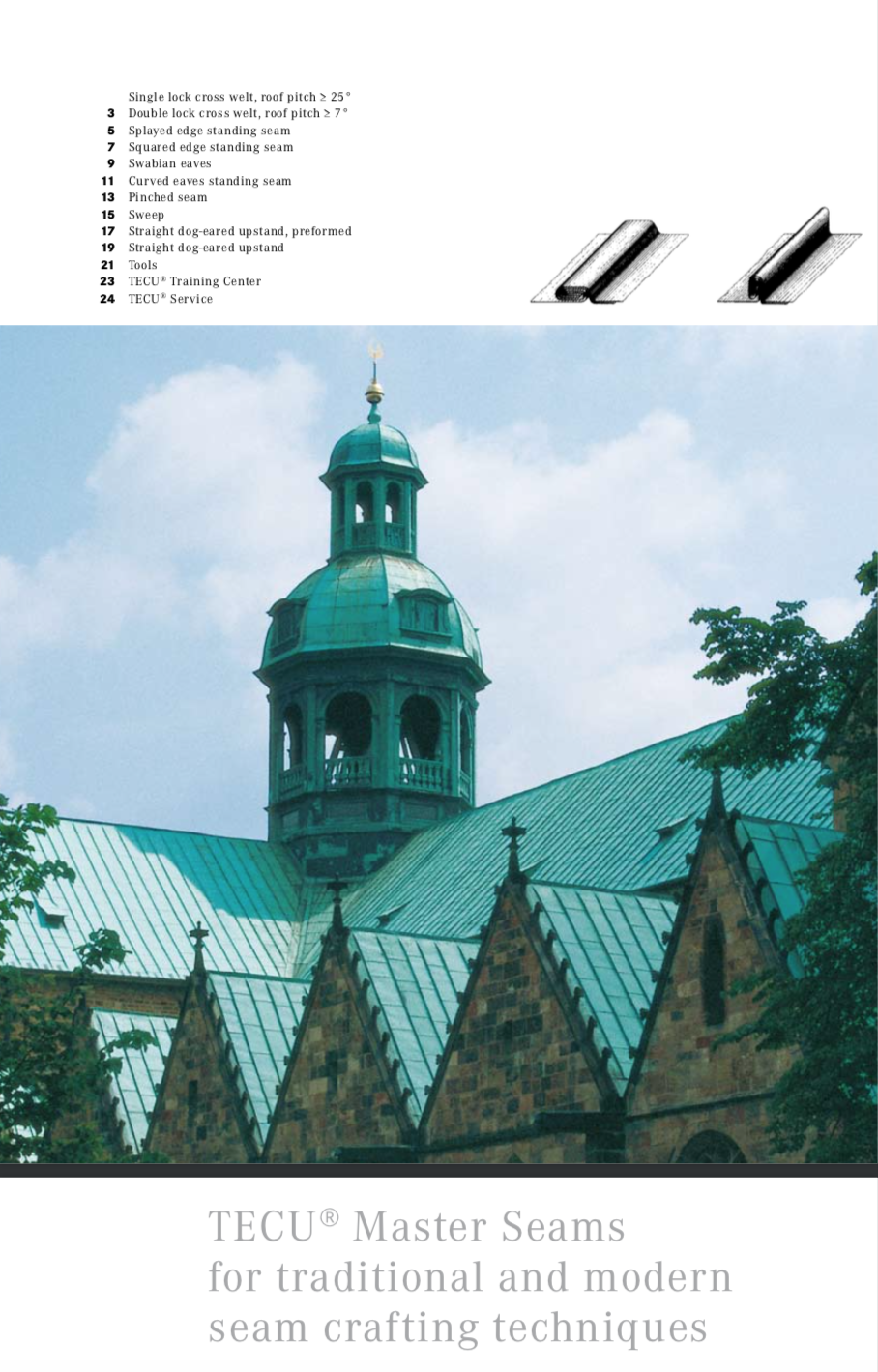

TECU Master Seams: a primer in metal roof seaming

There is very little information in english on traditional metal roofing. This is what prompted me to begin studying seaming, and publishing the metal roofing bible in 2018 after years of study and work in this field. I found all of the American resources lacking in this department, and most of the leaders in the field of historical roofing in America lacking in their knowledge of time-honored methods for folding and seaming. This short brochure is one of the few examples that show basic seaming techniques.

Although it does not offer instruction on how to create patterns for unique situations, it gives the reader the basics of the “knots” used to accomplish different details in metal roofing without cutting, soldering, or sealants. These techniques allow the roofing elements to be free-folded, and more importantly it allows the roof to be repairable in the future without disrupting the entire assembly. This is not possible with american flat-lock methods where pans are soldered together creating a monolith.

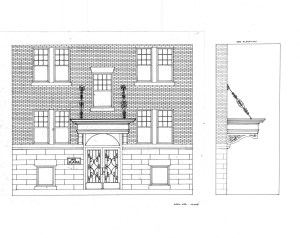

Throwback: helping “The Plaza” condo assn. at St. James Court navigate stifling restrictions from a very un-informed historical commission.

Posted 10th November 2008 by Kurtis

I’ve been working with the residents of this condo building for some time now to navigate the waters of the local landmarks ordinance with the intention of removing these hideous and poorly built entryway awnings. These things were assumed by the landmarks committee “experts” to be original, and therefore in need of preservation. I’m not sure if they ever did any true survey or research work to come to this conclusion because there was evidence all-over a classical portico that preceded the current installation.

These things are corroded through and besides being an eyesore, they are a burden to maintain and would be impossible to recreate with the condo association’s budget.

In this photo it is easy to see the “ghost lines” of the former entryway surround with a flat roof. The sheet metal rectangle against the wall is also covering a limestone lintel that would have fit perfectly inside the original surround.

After much back-n-forth with the “experts” at landmarks, we got our approval and demolition began! Further inspection upon demolition revealed even more clues. A cast stone lintel, previously covered by the barrel vault, flanks the doorway. The new design frames the stone lintel.

Posted 31st March 2009 by Kurtis

Things are starting to shape up on the Court. We finished the trim carpentry on one of the two structures today. Here are some photos of the progress:

Corbels installed…

View of the ceiling from the inside.

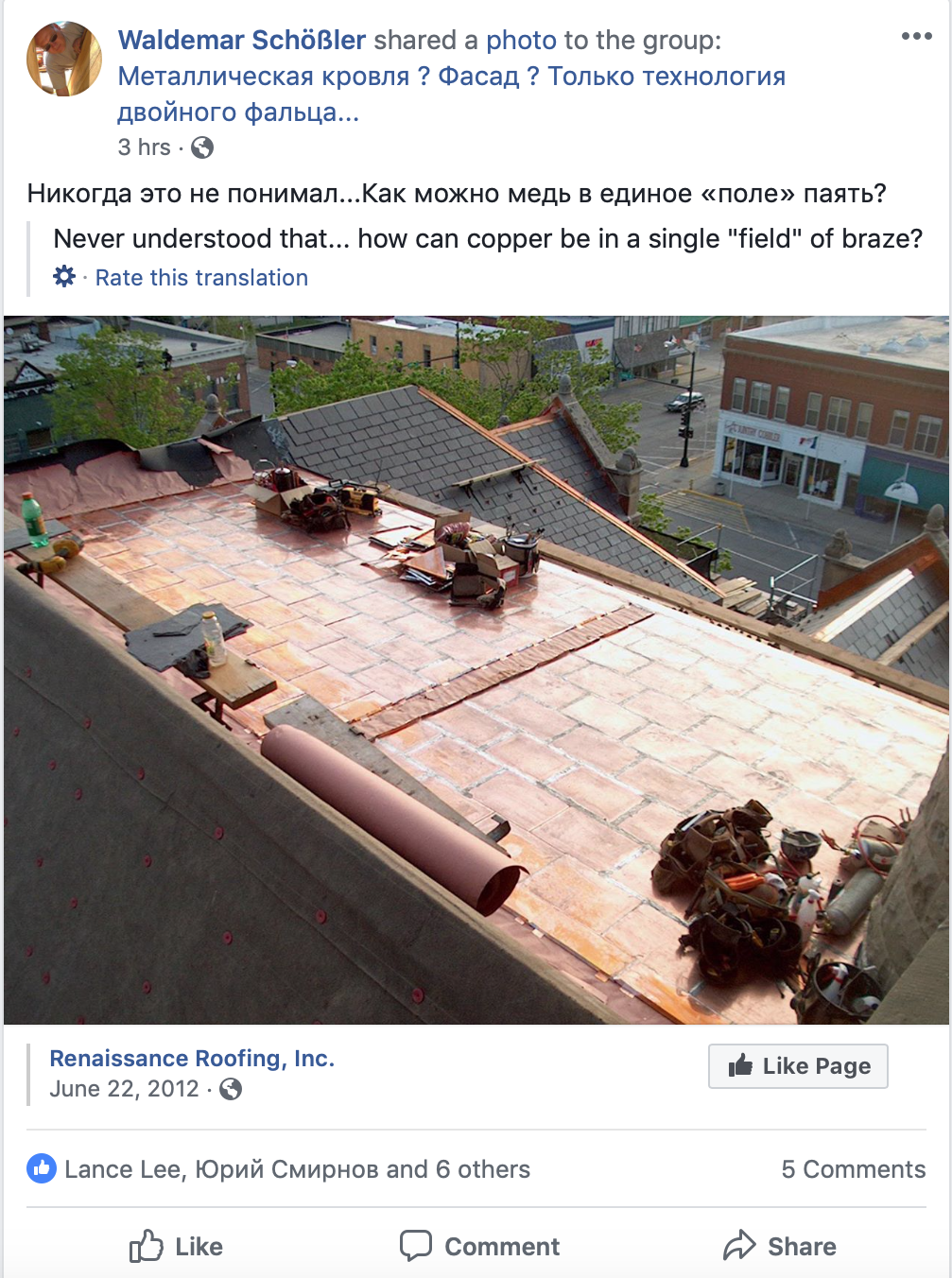

Renaissance Roofing, getting roasted.

In Europe, where the history and heritage of metal roofing comes from: flat lock was never used. It never even existed because they knew how to seam, and design their roofs properly.

They train for years to build actual permanent roofs, using methods they were adopted around the year 800 and are still in use today. Many of these european roofs have benchmarks for performing multiple centuries with no human intervention after the initial install.

Why is this important? It’s wasteful for one. Copper, and metal, and budgets on large public projects are not cheap in the US. The same amount of materials and labor could be applied with proper training and methods to produce much better results: results that will last centuries.

There is another issue: repairability. When you spend labor to slice up copper into “plates” fit them on the roof, and then solder them back together: you’e charged a whole bunch of money to put down a monolith, that will never be anything other than that. With free-seamed panels however if a repair of a single pan is ever required (bullets falling from the air, other trades mounting stuff and penetrating the roof at some point in it’s life… ) Then a single part of the roof can be repaired or re-worked without disturbing the entire assembly.

You must be logged in to post a comment.