The Internet's Own Historic, Traditional, and Permanent Building HQ

Hello everyone. This is my first post on kiânke. I represent the company “the first roof workshop”, the city of kharkiv.

Our team just came back from Kiev, where we participated in the construction service festival. Where we were invited by our partners company “kverb”. for the exhibition, we brought the first in Ukraine a machine-template for the manufacture of salary salaries.

Impressions Sea!!! New dating. Masters from all over Ukraine gathered. And also the cool guys from Belarus. Hello everyone

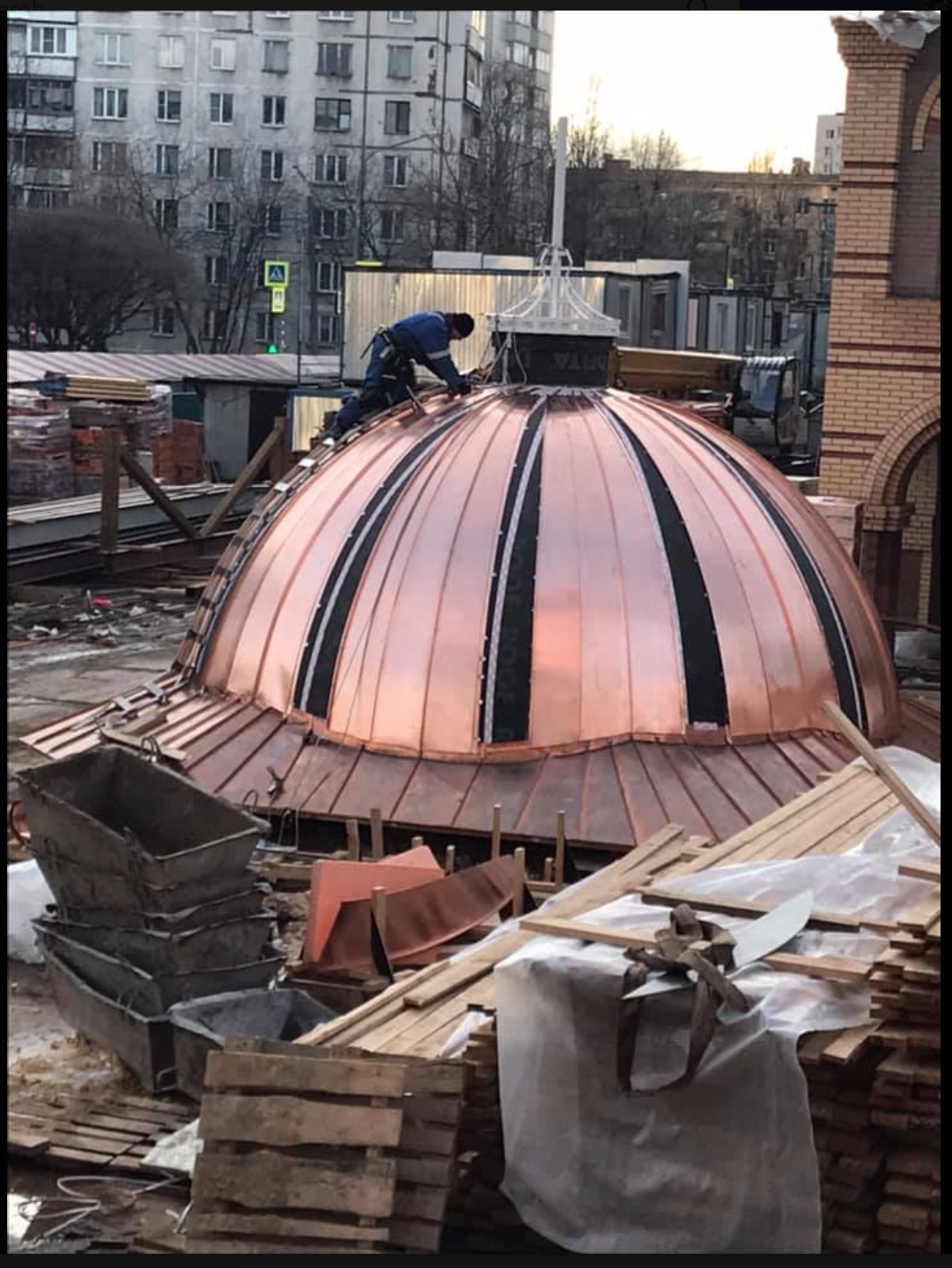

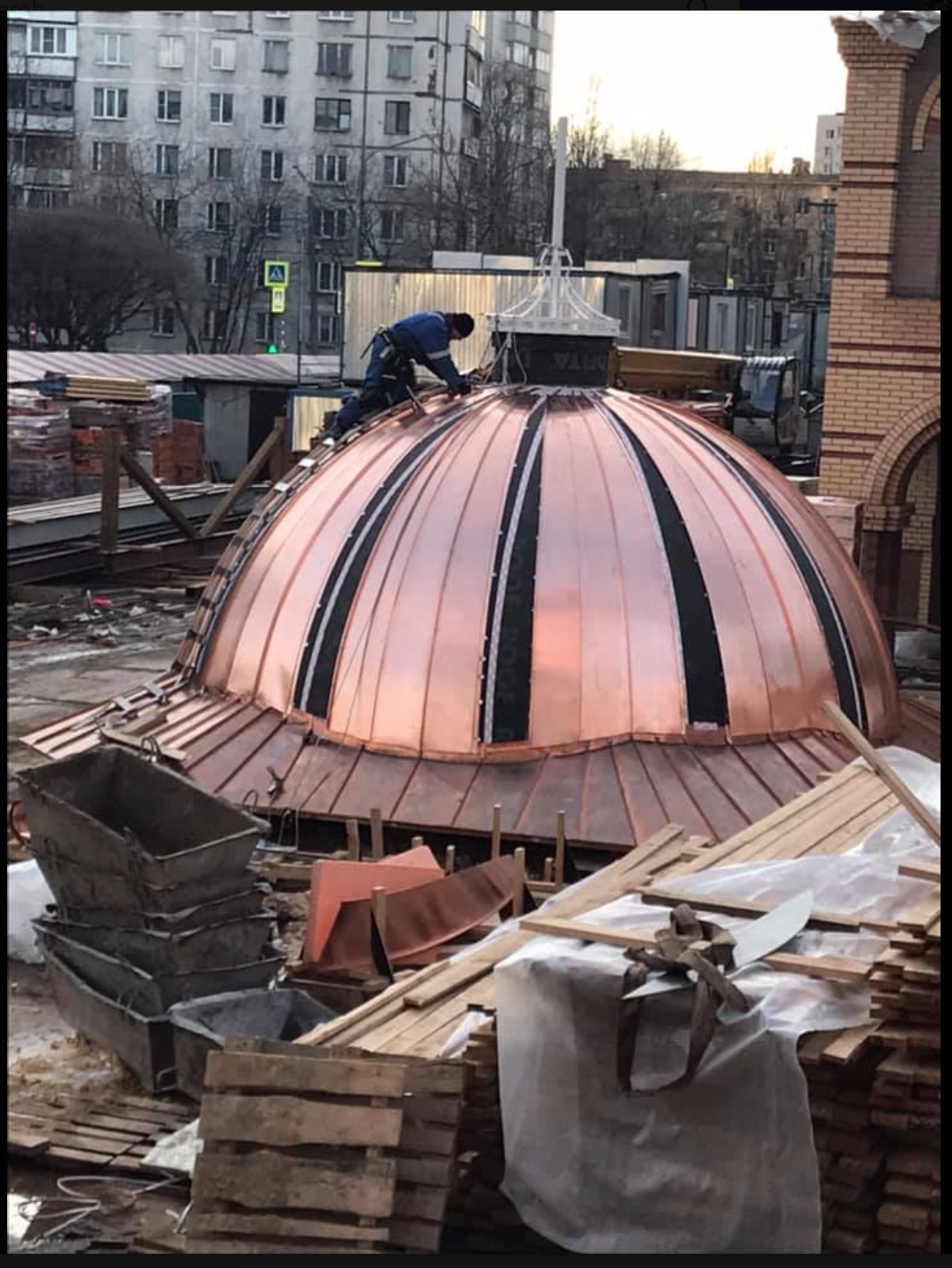

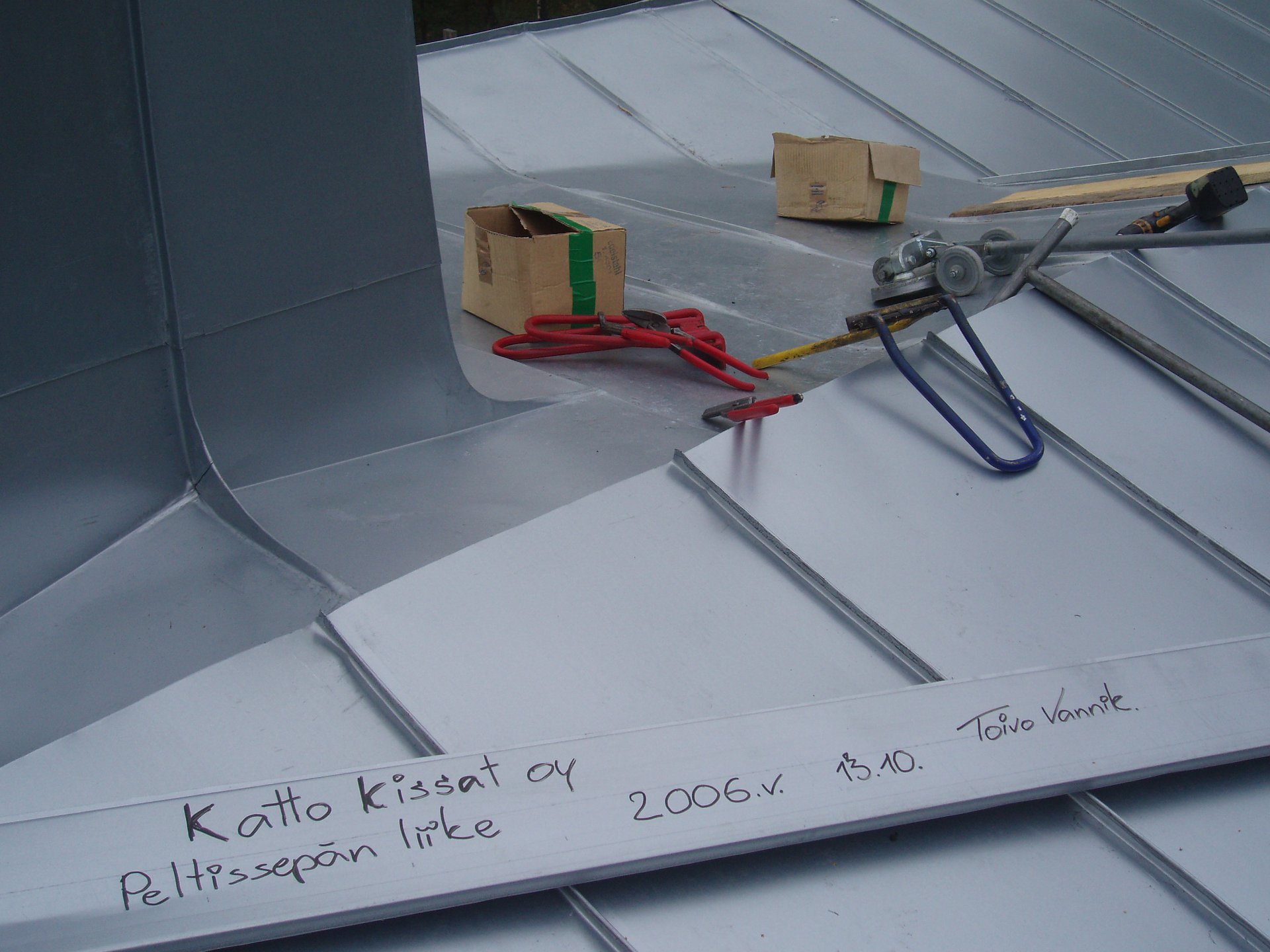

Great example of a classic metal roof with mechanical lock standing seam, and fully seam details on all the joinery. Even with the cap, it features full seaming in the valley and ridge transitions. This makes all the difference in longevity.

It’s hard to write about joinery in plain english and properly translate the concepts that are important to understand. Most folds take several steps of planning and operation, they don’t look pretty during the process so it’s not very photogenic. It is also not so much fun to watch except for someone who is learning how to seam.

This is the biggest issue in America is education: There are so few roofers (even “historic” roofers) who understand how to seam, because the market is making money training people to do sub-par methods with caps, and sealant, and screws.

We don’t even understand fully the impact of what we lose by choosing to continue the “production” roofing methods. Mainly: lost wealth. This goes for the whole exterior of the house. We chose to put our wealth in the pockets of manufacturers: producing cheap windows, plastic and aluminum siding, and veneers. These products might give you a temporary “curb” appeal to the un-educated when they are new, but over time that initial investment will depreciate, and need “remodeling” in a generation or two. This means there’s a secondary market for disposable roofs, siding, and windows that you are locked into every 20-30 years.

The more prudent way to build wealth in a property is to restore the exterior (strip and paint if wood, tuck point with lime putty in brick). The windows can also be restored, and when properly restored with a storm window they function just as well as those plastic replacements which do not last.

Durable methods and materials provide a lasting true value that will not be chipped away at by future needs to repair or remodel.

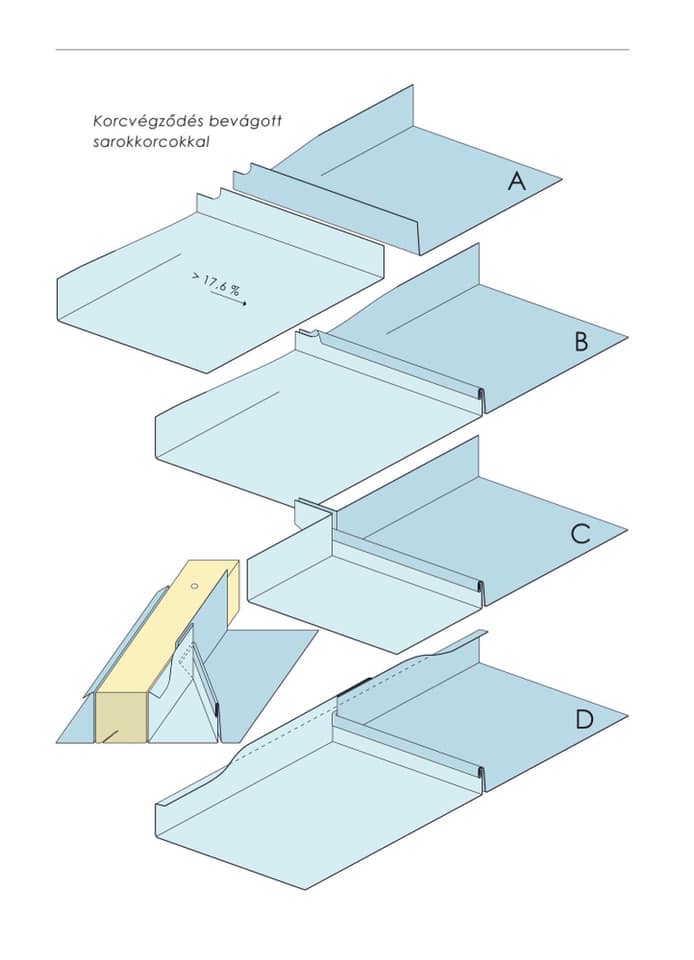

Translated by google from: http://www.krovlirussia.ru/book/texnika-dvojnogo-falca

The author is a Hungarian roofing engineer, Laszlo A. Santo. The owner of his own roofing company, who educated more than a dozen master roofers.

In his book, the author, relying on his forty-year professional experience, after ten years of computer development on the topic, offers the readers attention to the basic nodal connections of traditional roofing works on metal, carried out in digital form and put into practice. In the four-volume edition you will be able to get acquainted with the key connections of the work carried out, the prescriptions of professional rules and practical experience, supplemented by a collection of instructions, lectures and articles.

Each volume is devoted to a separate topic, but they are all closely interrelated. This edition will be interesting, of course, to roofers, architects, designers and other market participants, working with both metal and small-piece roofing.

Content:

Volume 1. Roof water discharge, linear coatings, structures

Volume 2. Metal parts for roofs from small-piece materials / elements

Volume 3. Seam cover

Volume 4. Rack and rebate cover

The cost of the book is 12,500 rubles.

This forum, on FB is absolutely one of the best sources for information and example photos for permanent, standing seam roofing. We rely on the translator service as almost nobody speaks english. Back in 2012, when I was studying folding and joinery techniques (with zero online resources in english) I used to pull the text one-by-one from PHP forums and paste into google translate. This is so much better as we can actually communicate; although it is somewhat broken.

This photo shows a really interesting valley concept, and the debate ensues… What is so unique and showy about this approach is that one whole side of the field had to be installed, and turned up. When the opposing side was installed: since the seams have to run in to and past the valley, it means they had to deform every field seam down, and lay them all over all the way up, so the pans would sit flush on the field. This is working blind. After that, they would have to close all of the connecting seams, and dress it down to fold the valley.

You must be logged in to post a comment.